- Joined

- Feb 14, 2018

- Messages

- 713

- Location

- United States

- Vessel Name

- Wanderlust

- Vessel Make

- 1999 Jefferson Rivanna 52'

Everybody should have a Ski aboard, let start the cloning process

L

What would those be? Ski-itos? Ski-lettes? Mini-Skis? ?

Everybody should have a Ski aboard, let start the cloning process

L

What would those be? Ski-itos? Ski-lettes? Mini-Skis? ?

Wifey B: Ski-ttles.

I agree. I think TF should create a special member category for individuals like Ski. Instead of “Guru”, I think “Hero” would be appropriate.

Gene...please post your findings when issue solved. Thx, PD

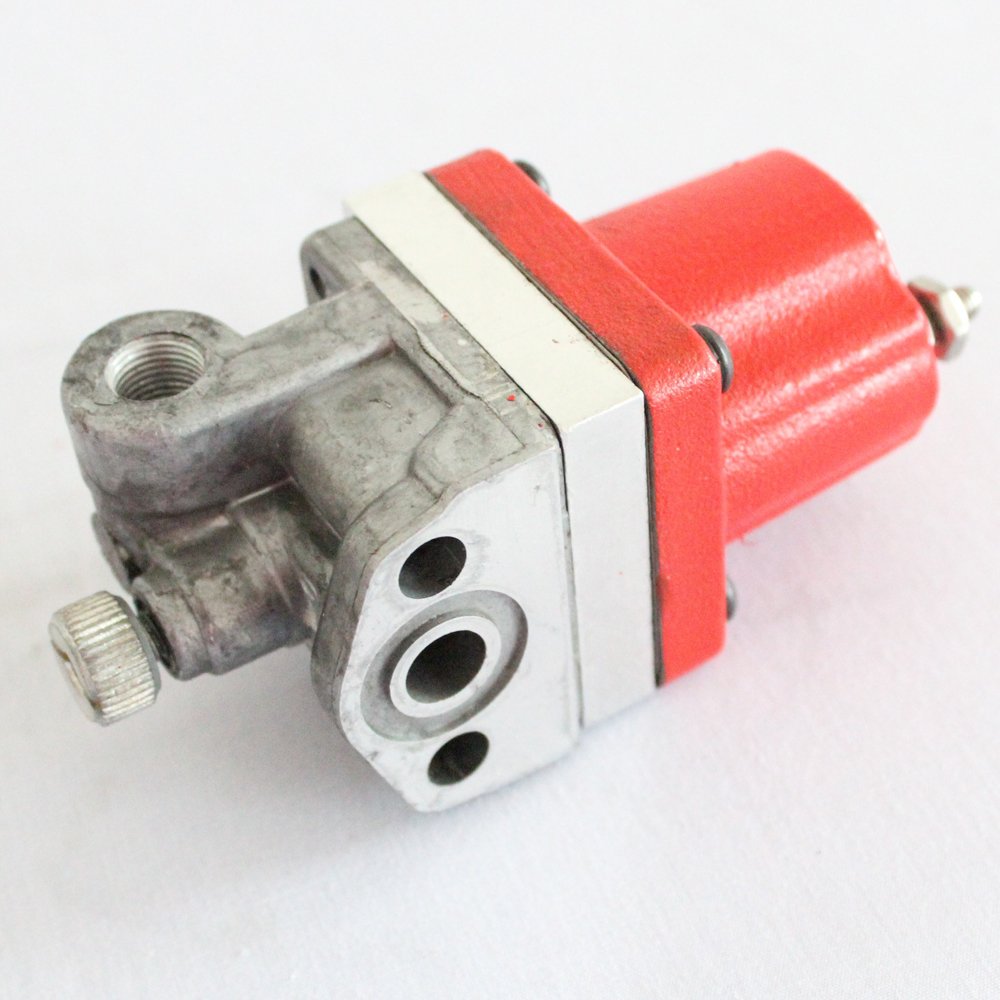

Simi- What engine do you have? Starter are all pretty similar, but what varies is how the shutdown is handled. Some are electric to stop, some are electric to run, some have a mechanical pull cable to stop.

Gene, nice to see that you found the problem. I know what you mean about learning about your boat and engine.

This story is the main reason I don't buy electronically controlled engines or boats with them. For 70 years plus, almost all diesels once started ran until out of fuel. Everything was mechanical. Many old style engines run for decades without repairs. Anything that interferes with a diesel engine running doesn't belong on a boat. Especially one that may go far from land.

Commercial operators forced into installing these unreliable engines, over time, end up carrying hundreds if not thousands of dollars in overpriced spares. And for what? Slightly better economy or a little cleaner exhaust from the smallest group of engine users in any country. The only people happy with the reliability are the ones selling replacement parts and services. Or maybe the tow services.

Yeah, it's an old guy rant, but really about change for worse. One thing nice about being old, I can live out my life running engines that will get me home.

Dave,

I would be a lot more comfortable if I knew WHY the breaker opened. The screws that mount it in place appear to have the original factory paint. I just finished removing the breaker, cleaning the connections and reinstalling it.

Hopefully it is just an age related issue (the boat is a 1999) and that replacing the breaker will fix everything. I am not electrically savvy enough to know the other possible reasons that it opened.

Gene

You could have made the same argument about electronic controls in cars and they seem to work out pretty well. I have had mechanical controlled diesels and electronically controlled diesels and don’t want to go back to mechanical. My current electronic engines (Cats) just passed 4000 hours and are awesome. They run clean and smoke free from a cold start. They will idle for a week or run at full throttle for hours and I get no smoke, fumes, or unburned fuel. Its progress I am happy to have. And by the way, I’m not a young guy.

I know of several boats build in countries with all the flash diagnostic gear and mechanics at hand and all was good.

They then went to remote areas like PNG, Indo, Solomons,Vanuatu where diagnostic tools were probably a stick and a hammer and they were a pita.

A couple of them that remained as work boats had the modern engines replaced with old rebuilt simple engines, others had to came back to civilisation.

YetMine haven’t had any issues .

so repair capability hasn’t been relevant. Also I limit my travels to the west coast of North America and the Caribe and service is generally reasonably available.

Dave,

I would be a lot more comfortable if I knew WHY the breaker opened.

That is a good attitude. Could be age, could be an intermittent short. So take this time to find a replacement in case the breaker fails permanently. Also eyeball the entire harness for chafe and cracked insulation.

.

Simi- Your NTA 855's use a PT pump that has been used in a bazillion road tractors which use an electric to run solenoid. Lose power, engine stops. Sounds like that is your arrangement too. I think there are industrial versions that use an electric to stop, but I have never looked into it. Might be as simple as a solenoid swap and then replace you toggle with a stop push button.

.