You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where old zincs go after death

- Thread starter eagle419

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

If you have a half dozen zinc ends lodged in your heat exchanger you aren't changing them often enough. Change them when they are only 1/3 gone. That leaves enough to stay screwed into the plug and enough meat to let you unscrew them. A little grease, permatex, lanacote on the threads makes it easier to unscrew and retards losses there. Or maybe they aren't screwed in tight enough and drop out when you unscrew the plug.

Most of those in the pic look like they fell off inside when someone tried to unscrew the plug to replace them.

David

Most of those in the pic look like they fell off inside when someone tried to unscrew the plug to replace them.

David

Last edited:

diver dave

Guru

- Joined

- Jan 13, 2017

- Messages

- 2,570

- Location

- United States

- Vessel Name

- Coquina

- Vessel Make

- Lagoon 380

I'll bet those zincs work fine, as they sit.  no need to mess with zinc for a number of years.

no need to mess with zinc for a number of years.

I'll bet those zincs work fine, as they sit.no need to mess with zinc for a number of years.

I appreciate the humor, but I don't think that those zincs are providing any protection. When they rattle around loose like that they develop a coating of zinc carbonate and other compounds on the surface that insulates them from the metal. After a while they stick in one place due to the zinc coating. The zinc needs to maintain good contact with the screw plug and in turn with the heat exchanger case and tube bundle to do any good.

It takes a little trial and error to find out how tight to screw a zinc into its plug: Too tight and it will twist off when you try to replace it; too loose and it will back out when you unscrew the plug and fall off inside.

David

diver dave

Guru

- Joined

- Jan 13, 2017

- Messages

- 2,570

- Location

- United States

- Vessel Name

- Coquina

- Vessel Make

- Lagoon 380

Yep, of course you are right. I had a zinc situation with an oil cooler zinc set up. The water velocity was so high, that the zinc would erode and deposit over the tube openings as a hard "mud", and cause a lack of flow. Trouble was, the cooler did not have a clean out port. Most every engine HE at least allows access to remove the dead bodies inside.

HopCar

Guru

- Joined

- Aug 20, 2011

- Messages

- 5,308

- Vessel Name

- Possum

- Vessel Make

- Ellis 28

When I was a kid, I’d pick up bits of zinc like that in boat yards. My friends and I would put about a pint of muriatic acid in a plastic pot, drop some of the zinc in and hold the opening of a plastic bag over the pot. The bag would fill with hydrogen gas. Then we’d tie a lit sparkler dangling a foot or two below the bag and let it go. Don’t know why we didn’t blow ourselves up or set something on fire.

kchace

Guru

- Joined

- Sep 29, 2013

- Messages

- 2,265

- Location

- USA

- Vessel Name

- Shalloway

- Vessel Make

- Defever 44, twin Perkins

My HEat exchangers looked rather similar. The PO changed the zincs all right, he just never looked inside. There must have been have a dozen old broken off zincs in each heat exchanger.

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

Just changed my zinc a couple weeks ago. I have three, two in my aftercooler and 1 in the heat exchanger. I find that I often can move the lower anode in the aftercooler to the upper position. This time, they all looked bad enough that I just replaced all of them. They aren’t expensive so it doesn’t bother me.

I also don’t want to let it go so long that the zinc breaks off when I try to take it out of the cap. It happened the first time I replaced the anodes.

Another odd thing, is that the threads on the anodes supplied by Cummins are a different thread than those I get from boatzinc.com. As such, the next time I order anodes I’m going to order a set with caps, just so I have a spare.

I also don’t want to let it go so long that the zinc breaks off when I try to take it out of the cap. It happened the first time I replaced the anodes.

Another odd thing, is that the threads on the anodes supplied by Cummins are a different thread than those I get from boatzinc.com. As such, the next time I order anodes I’m going to order a set with caps, just so I have a spare.

timb

Guru

- Joined

- Sep 12, 2017

- Messages

- 572

- Location

- usa

- Vessel Name

- true heading

- Vessel Make

- marine trader 38 dc

I went to change mine and I guess it broke I can see it in the hole but it is loose from the cap it is on the list to fix . I wanted to pressurize the coolant while I have the end off to check for heat exchanger leaks.

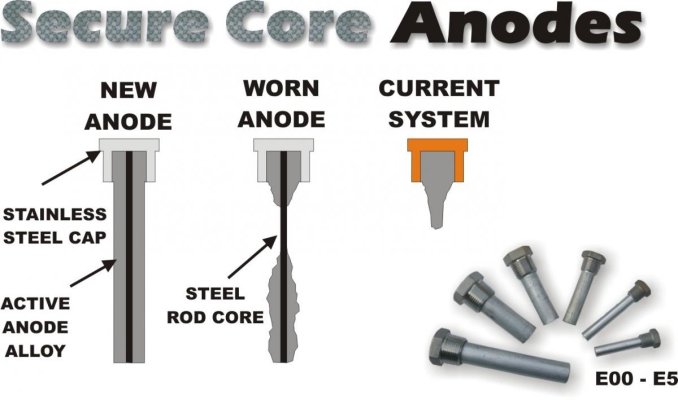

We had the same problem with the heat exchanger zincs breaking/wearing off. When we changed to aluminum anodes, we also changed the one on our heat exchanger to one manufactured by Peformance Metals. They have a wire core and so far I haven’t have any break off when they get changed.

Attachments

Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

We had the same problem with the heat exchanger zincs breaking/wearing off. When we changed to aluminum anodes, we also changed the one on our heat exchanger to one manufactured by Peformance Metals. They have a wire core and so far I haven’t have any break off when they get changed.

Hey... that is pretty slick!

Question about loctite or even anti-seize. Do you or do you not need to have a very good connection to ground for them to work? Would not substances hinder such a connection?

(Asking for a friend.) ;-)

C lectric

Guru

Hey... that is pretty slick!

Question about loctite or even anti-seize. Do you or do you not need to have a very good connection to ground for them to work? Would not substances hinder such a connection?

(Asking for a friend.) ;-)

No, as long as you snug up the anode in the cap there will be metal to metal contact as the threads will push any liquid or sealer out. The Loctite locks by filling the gaps left and basically glueing the two together.

I also use a thread sealer , Rectorseal #5, on the zinc caps where they screw into the heat exchanger. Actually I use the Rector on the zinc pencil threads also.

If you don't believe then use an ohmmeter to double check.

kchace

Guru

- Joined

- Sep 29, 2013

- Messages

- 2,265

- Location

- USA

- Vessel Name

- Shalloway

- Vessel Make

- Defever 44, twin Perkins

Hey... that is pretty slick!

Question about loctite or even anti-seize. Do you or do you not need to have a very good connection to ground for them to work? Would not substances hinder such a connection?

(Asking for a friend.) ;-)

You do need a good connection but the sliding action within the threads of tightening the fitting is enough to push something like never seize out of the way. Don't know why one would want to use loctite, typically the threads are tapered pipe - snug it up and its not going to loosen. Because of the metals involved you shouldn't normally even need never-sieze.

Ken

Similar threads

- Replies

- 154

- Views

- 21K

- Replies

- 9

- Views

- 2K