Several years ago I extended my swim step.*

The original was slatted Teak, similar to most Taiwan built 80s trawlers.* Trouble was, it was next to useless, too narrow to walk on without hanging on, to narrow to sit on without feeling like you were in danger of falling off. Approximately 20 inches deep, which may sound like a lot, but with the slope of the transom taking out a few inches, and with davits attached to the transom taking out several more inches, only about the outer 8 to 10 inches were useful.

On my last boat, A sailboat with a fairly broad transom, I added a swimstep.* I made it our of fibregalss, from a female mould, and had SS supports welded up.* For Retreat, I wanted to retain the original appearance.

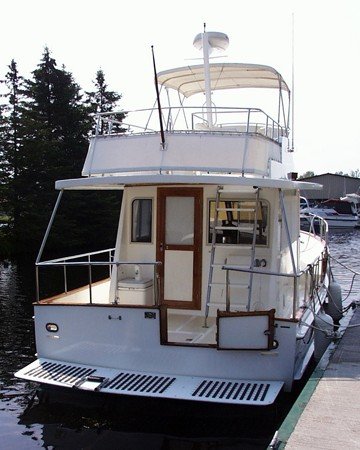

The extended version in 33 inches deep and results in safety and comfort. The picture shows the completed step.* I bought 2 teak planks,* 2x8x14', and a smaller one, 1.5x8x10', for about $500.00.* From those I cut strips to match the originals, and fitted them all together between the original swimstep and the transom, so as to re-use all of the original step. I turned it over, so as to put the weathered surface on the bottom and to match the new with the unweathered former bottom surface.* I had to buy new supports, as the original supports were not in good shape, and couldn't be easily adapted to the new length.* I had those made up out of stainless steel. I don't recall how much I paid for the SS fabrication, but it didn't seem like a lot at the time.* I was also able to adjust the height off the water, which I raised a couple of inches, and I put all of the attachment bolts above the water line.* I also had to extend the ladder, so it would still stand against the transom and deploy just over the stern edge of the swimstep.

The level of woodworking skill required is not high.* Lots of clamps are required, for when the pieces are being assembled.** I think the appearance is quite inconspicuous, it looks like it was always that size, which was the plan.