capeshore

Veteran Member

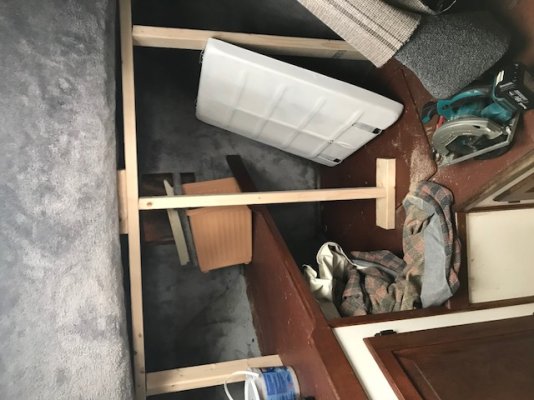

Hey Y'all, so the journey begins.New to the forum and we just purchased a 78 MK1 from a neighboring boat club (up in Boston area) and it's an upgrade from our 26 Sundancer style boat that was just not us but we had a good 8 years with her.

Going to make this a thread to show all the work that will be getting done in the next year (or more )

)

Tons of soft decks, rewiring, painting,plumbing, flooring, and gene/engine work ahead hopefully some can find it useful and the rest can get a kick out of my Tom Hanks money pit boat

We plan on keeping her for a long time..It's our second to last boat..maybe last! Love it and the potential she has. Anybody in the Boston area always welcome for a stop by to give advice I would happily trade for a beer. -Dave

Going to make this a thread to show all the work that will be getting done in the next year (or more

Tons of soft decks, rewiring, painting,plumbing, flooring, and gene/engine work ahead hopefully some can find it useful and the rest can get a kick out of my Tom Hanks money pit boat

We plan on keeping her for a long time..It's our second to last boat..maybe last! Love it and the potential she has. Anybody in the Boston area always welcome for a stop by to give advice I would happily trade for a beer. -Dave

Attachments

Last edited: