firstbase

Guru

- Joined

- Nov 6, 2016

- Messages

- 1,644

- Location

- United States

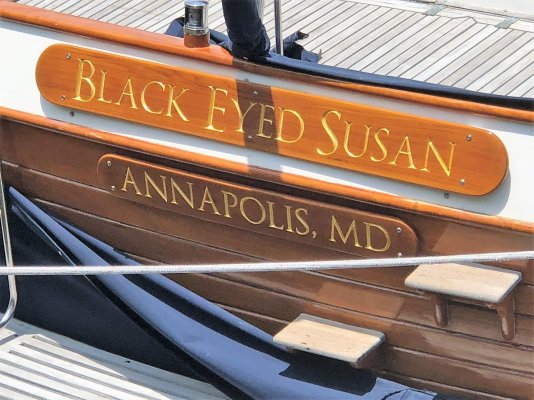

- Vessel Name

- Black Eyed Susan

- Vessel Make

- Grand Banks 42' Classic

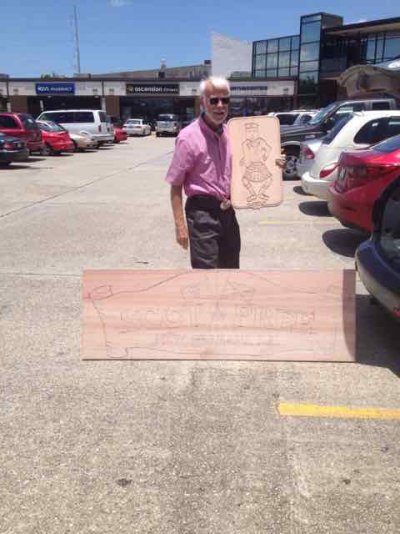

Going to varnish new mahogany name boards and have a concern in that the transom board will be new and straight. However, when I install it will have to follow a bit of a curve on the transom. Not sure how much but think about 1/2" to 1" from center on each end of a 55" long board. I can finish the boards but install will then stretch the varnish on top, bunch it underneath. I don't want to start Varnish Wars Chapter 103 but is there one varnish or a particular type (i.e. high oil content, etc) that would stand up to this or am I just overthinking it and any will do fine? I thought about bending the board and varnishing it with the curve but that would seem to be a pain.