Fotoman

Guru

- Joined

- Nov 12, 2009

- Messages

- 649

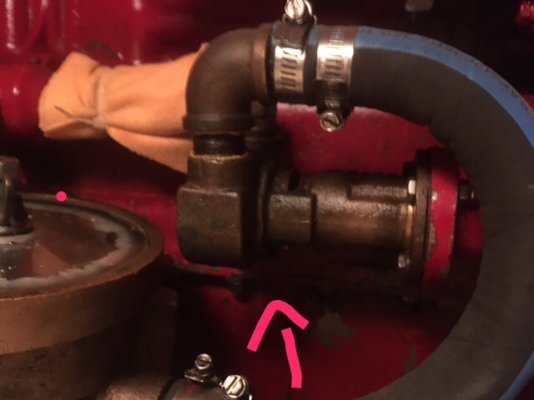

I just noticed that my water pump is leaking when the engine is running. It's approx a drip every second. Not super familiar with the insides of this component but I assume it must be a worn out seal?

Is it a critical issue or can I keep using the boat for a little while until I can fix it?

Indicated on the picture when the drip is coming from.

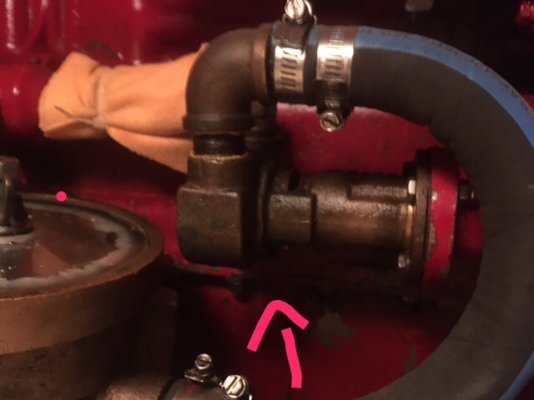

Is it a critical issue or can I keep using the boat for a little while until I can fix it?

Indicated on the picture when the drip is coming from.