Coupling are still tight. The machinists knew what interference fit was correct and made the adjustment. Believe me, I had to pull them off with a gear puller.

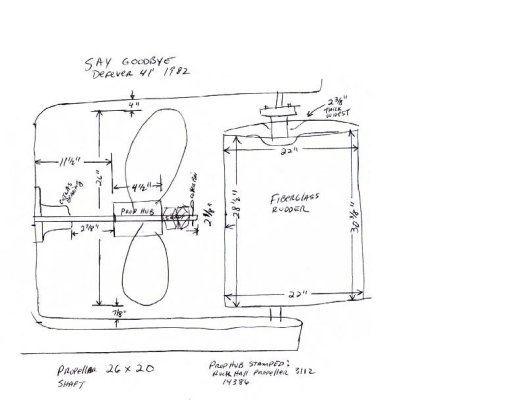

Reinstalled shafts, props, rudders and splashed boat back in harbor.

Waited till the next day to perform shaft alighment. Alighment not very far off. Only minor adjustment required.

Performed a slow speed run in the Sound to adjust the stuffing boxs. Check their temperature with a remote gun.

Full throttle run next. Good and steady with no vibration.

It was hard work and cost about $1.5K total but now the boat feels good. As the commercial says "Priceless".

Unfortunately the repitching of the props knocked about 200 rpm off the top. Stilll I have a plan to deal with that. The new turbo chargers are sitting on my work bench right now. Just waiting to find time to fabricate some oil lines.

I still have a question about those stuffing boxes, what temperature should they run at?