DHeckrotte

Guru

We've got three scuppers on each side. They're the usual fiberglassed-in connection between the hull and the deck. The forward four are apparently in good shape, not obviously cracked. I presume that area of hull and deck are affixed together.

The aft scuppers are about as far aft as you could have them. The boat is an Europa-styled sedan so there's a generous back porch over a generous Lazarette. There is precious little tying the hull to the deck except the scuppers, the bulkhead under the aft end of the house, two glassed-in beams framed into the transom, and the surround of the transom door. The two scuppers are cracked around their inboard ends and the transom door sill is also cracked. These TTs were built with side and transom doors in various places (center, to port, to starboard, sometimes on one or both of the sides). I think that they cut 'em in where the dealer wanted them and they made up the jambs and sill later which would explain why my door's edges and its jambs all show the end grain of a wood member up under the caprail.

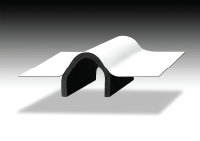

Ahh, but back to scuppers! I've spent quite a few hours in the Lazarette this spring (swim platform bracket mounting, genset exhaust redo, limber holes, shelving redo, etc.) and am disinclined to be there more! The scuppers definitely leak and they look cracked from above. I had thought of glassing/tabbing the deck to the hull in a few more places around the back porch but this is work for a young, supple (and low-ranking) workie. I had also thought of re-glassing/recreating the scupper while working from on deck. This weekend I had the thought of bandaging across the crack with, say, white EPDM or PVC roofing material. Expansion joints and scuppers in buildings are often done in similar ways; see pic.

Thoughts? Experiences? Suggestions?

The aft scuppers are about as far aft as you could have them. The boat is an Europa-styled sedan so there's a generous back porch over a generous Lazarette. There is precious little tying the hull to the deck except the scuppers, the bulkhead under the aft end of the house, two glassed-in beams framed into the transom, and the surround of the transom door. The two scuppers are cracked around their inboard ends and the transom door sill is also cracked. These TTs were built with side and transom doors in various places (center, to port, to starboard, sometimes on one or both of the sides). I think that they cut 'em in where the dealer wanted them and they made up the jambs and sill later which would explain why my door's edges and its jambs all show the end grain of a wood member up under the caprail.

Ahh, but back to scuppers! I've spent quite a few hours in the Lazarette this spring (swim platform bracket mounting, genset exhaust redo, limber holes, shelving redo, etc.) and am disinclined to be there more! The scuppers definitely leak and they look cracked from above. I had thought of glassing/tabbing the deck to the hull in a few more places around the back porch but this is work for a young, supple (and low-ranking) workie. I had also thought of re-glassing/recreating the scupper while working from on deck. This weekend I had the thought of bandaging across the crack with, say, white EPDM or PVC roofing material. Expansion joints and scuppers in buildings are often done in similar ways; see pic.

Thoughts? Experiences? Suggestions?