Lou_tribal

Guru

We are in the process of a rejuvenation of our boat. Started some weeks ago as soon as snow melt made it possible.

First thing, new paint in the aft bilge, deep cleaning of the bilge pump that was in a disgusting state, re wiring of the bilge pump with waterproof removable connectors (the PO the wire to force the pump on), and some new grease on the shaft bearing and gimbals (is it the right term?).

New fresh bilge paint (Interlux bilgekote):

Waterproof connectors for the pump (coming from solar panel world):

Pump cleaned and finally back in place:

V-sitting and saloon benches were sanded, one coat of Interlux Pre-Kote applied, awaiting for 2 coats of off-white Interlux Brightside (we wanted clean benches before putting the new cushions on).

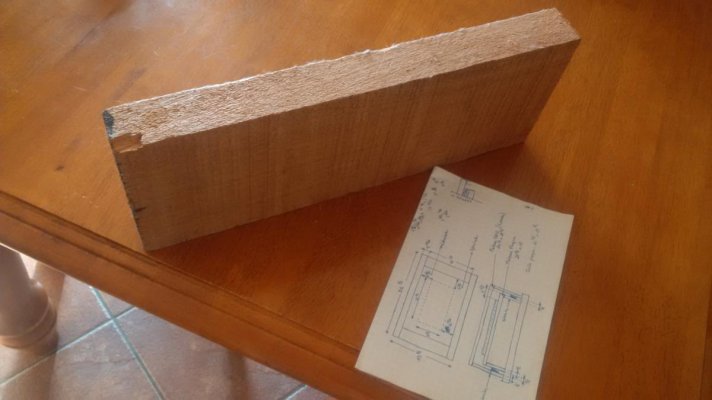

New cooler in the bow insulated and sanded, next step will be to join the insulation plates and glaze it with FB and epoxy.

Lot of work coming ahead!

L.

First thing, new paint in the aft bilge, deep cleaning of the bilge pump that was in a disgusting state, re wiring of the bilge pump with waterproof removable connectors (the PO the wire to force the pump on), and some new grease on the shaft bearing and gimbals (is it the right term?).

New fresh bilge paint (Interlux bilgekote):

Waterproof connectors for the pump (coming from solar panel world):

Pump cleaned and finally back in place:

V-sitting and saloon benches were sanded, one coat of Interlux Pre-Kote applied, awaiting for 2 coats of off-white Interlux Brightside (we wanted clean benches before putting the new cushions on).

New cooler in the bow insulated and sanded, next step will be to join the insulation plates and glaze it with FB and epoxy.

Lot of work coming ahead!

L.

:

:

Anyway it is mostly cosmetic work in progress so no drama.

Anyway it is mostly cosmetic work in progress so no drama.