Ok, I have another question for all you metal boat owners.

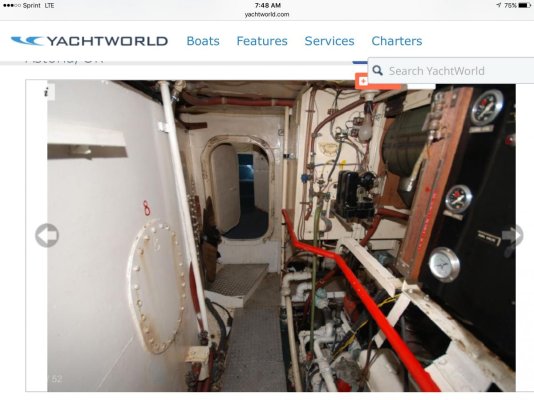

I am putting in a new ac panel today. I do not trust the old ac at all! So should I connect the earth ground (green) to the hull? My guess is no. I should also say I will be installing an isolation transformer in the very near future, but not today. But i will within a couple months.

Obie

Thank you

I am putting in a new ac panel today. I do not trust the old ac at all! So should I connect the earth ground (green) to the hull? My guess is no. I should also say I will be installing an isolation transformer in the very near future, but not today. But i will within a couple months.

Obie

Thank you