dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

Rather than hijack a thread I thought I would start another.

I have wanted to do an oil pan heater for a while and now seems like a good time. Tony Athens discusses them well at sbmar.com.

I checked the pan on my Cummins QSB 5.9L 380hp. It was built in 2008 and placed in service in 2010.

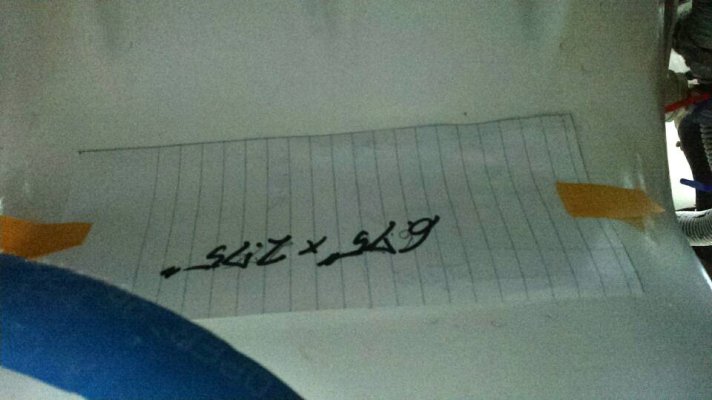

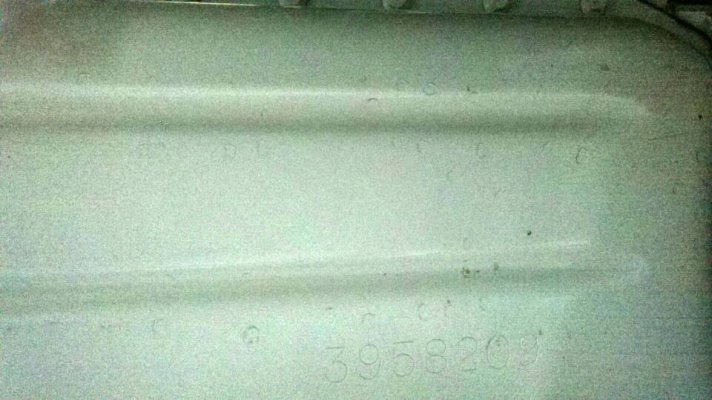

The bottom of the oil pan has indented ribs that run longitudinally along the shallow portion of the oil pan. The deep portion of the pan has the oil drain line in it. I'd like to figure out how to install this. Here are some photos. It was very hard to try and get a photo since there is only a few inches clearance to get the camera there.

Aft, port side of the oil pan.

Forward side of the starboard side of the oil pan.

Aft, starboard side of the oil pan.

Bottom of the shallow section of the oil pan on the forward 2/3's

Bottom of the pan looking aft towards the deep portion of the pan.

I have wanted to do an oil pan heater for a while and now seems like a good time. Tony Athens discusses them well at sbmar.com.

I checked the pan on my Cummins QSB 5.9L 380hp. It was built in 2008 and placed in service in 2010.

The bottom of the oil pan has indented ribs that run longitudinally along the shallow portion of the oil pan. The deep portion of the pan has the oil drain line in it. I'd like to figure out how to install this. Here are some photos. It was very hard to try and get a photo since there is only a few inches clearance to get the camera there.

Aft, port side of the oil pan.

Forward side of the starboard side of the oil pan.

Aft, starboard side of the oil pan.

Bottom of the shallow section of the oil pan on the forward 2/3's

Bottom of the pan looking aft towards the deep portion of the pan.

Last edited: