ksanders

Moderator Emeritus

I have my handy dandy sailrite sewing machine.

I have completed several small projects and have built enough skills to start my rear cockpit enclosure.

I have also watched the sailrite video series on building a cockpit canvas, so I have their opinion of the best method.

I still have some questions though. Especially since there are lots of different ways to design the enclosure.

1. Thinking of the zippers between panels. Some jobs I've seen have little flaps over the zippers, others don't cover the zippers. What do you do?

2. Thinking of the zippers between the panels. Has anybody used industrial velcro instead of zippers? Are there reasons velcro might be a bad idea? The reason I ask is my current bimini has 2" velcro beteen two sections and has held up well.

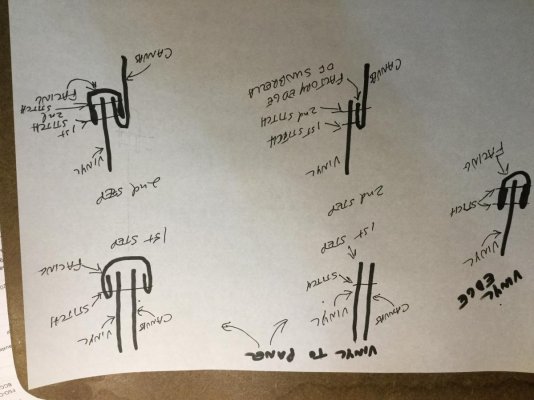

3. Thinking of the panel design... Do you use trim tape, or do you hem or double hem to finish your edges.

4. Thinking about the windows... Do you prefer to build your panels around the windows, or attach your windows to the panel, possibly cutting out the window? For example how would it look if you built a panel, positioned the window, cut out the panel and finished the edge, then sewed A window to that with a piece of trim tape around the window.

Thanks!!!

I have completed several small projects and have built enough skills to start my rear cockpit enclosure.

I have also watched the sailrite video series on building a cockpit canvas, so I have their opinion of the best method.

I still have some questions though. Especially since there are lots of different ways to design the enclosure.

1. Thinking of the zippers between panels. Some jobs I've seen have little flaps over the zippers, others don't cover the zippers. What do you do?

2. Thinking of the zippers between the panels. Has anybody used industrial velcro instead of zippers? Are there reasons velcro might be a bad idea? The reason I ask is my current bimini has 2" velcro beteen two sections and has held up well.

3. Thinking of the panel design... Do you use trim tape, or do you hem or double hem to finish your edges.

4. Thinking about the windows... Do you prefer to build your panels around the windows, or attach your windows to the panel, possibly cutting out the window? For example how would it look if you built a panel, positioned the window, cut out the panel and finished the edge, then sewed A window to that with a piece of trim tape around the window.

Thanks!!!