cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

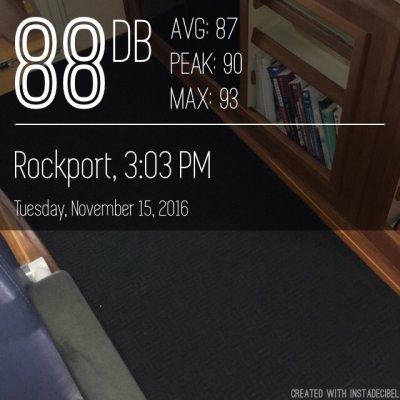

Was running the generator the other day and started wondering why it was so damn loud.

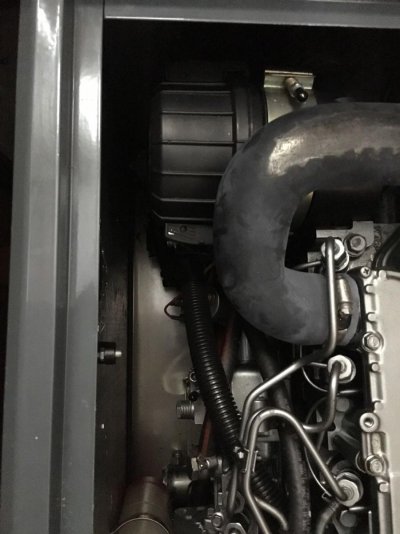

First of all, the generator is mounted directly below the pilot house in its own little "room", and it has a full enclosure. The generator is only about 4" from the floor of the pilothouse however, and the wooden floor has no insulation, so I'm guessing that is part of my problem. I thought about putting carpet and a sound absorbing barrier but I really don't want to cover up the pretty wood sole.

Other problem is vibration. The gen seems to vibrate the entire boat. The engine is isolated from the drip pan with traditional rubber mounts but the stainless steel pan is then directly mounted to the floor of the "generator room". Looks like this:

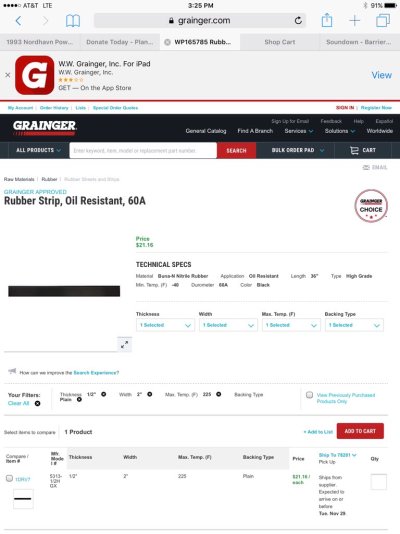

I saw on sundown some various bushings that maybe I could use to isolate the pan mounts to the boat? Think that would help much?

I will be at the boat later today for actual gen pics as it's mounted. Can't remember what the floor is made of where it's mounted so don't know if I can install a fancy bushing system-- I think it's just lag bolted into the floor but could be wrong.

Maybe just use a fat rubber washer?

First of all, the generator is mounted directly below the pilot house in its own little "room", and it has a full enclosure. The generator is only about 4" from the floor of the pilothouse however, and the wooden floor has no insulation, so I'm guessing that is part of my problem. I thought about putting carpet and a sound absorbing barrier but I really don't want to cover up the pretty wood sole.

Other problem is vibration. The gen seems to vibrate the entire boat. The engine is isolated from the drip pan with traditional rubber mounts but the stainless steel pan is then directly mounted to the floor of the "generator room". Looks like this:

I saw on sundown some various bushings that maybe I could use to isolate the pan mounts to the boat? Think that would help much?

I will be at the boat later today for actual gen pics as it's mounted. Can't remember what the floor is made of where it's mounted so don't know if I can install a fancy bushing system-- I think it's just lag bolted into the floor but could be wrong.

Maybe just use a fat rubber washer?