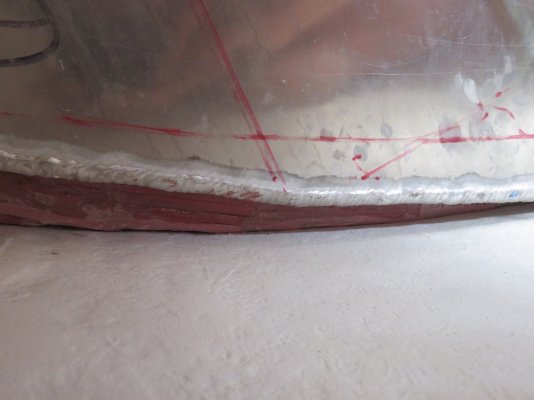

We installed the starboard tank and finished the exterior tank plywood today. I have no idea what builders used before there were hot glue guns to make templates. We got the front panel right on the first try. We'll install the perforated aluminum when we do the ceiling and have the port tank completed using the same templates.

The engine room is getting smaller which is a good sign.

The engine room is getting smaller which is a good sign.