McGillicuddy

Guru

- Joined

- Dec 4, 2015

- Messages

- 754

- Location

- USA

- Vessel Name

- Scot Free

- Vessel Make

- Cheoy Lee 53' Efficient

In continuation of a discussion on a thread I inadvertently hijacked, I had posted that I had spent a year refitting a Cheoy Lee Efficient Model motor yacht. Here are some of the details. As time goes along I will post more detailed info and pictures of the process. I hope that others with Cheoy Lee trawlers and motor yachts will chime in as there is no special section of the forum dedicated to the brand. We left off the other thread with this post by Dispatch:

McGill; This is incredibly helpful and it sounds like you got good value for the $$ spent. With the exception of the mechanicals, sounds like you took almost everything down to bear hull and did the cosmatics. I'm sure she looks incredible!! I'm keeping your list as I feel I could be facing a similar situation. How much work did you do yourself? Sounds like you did a lot -- a lot. For that money and what you did - a lot! I like all of your ideas including the Capt's gig ...... very cool for those shallow inlets. You obviously picked a yard to have some of the work done ..... what were the considerations for that choice? Did you live abroad during the dry dock/refit? You've got a great eye for customizing. When you say "good bones" can you be more explicit? Choey Lee is a reputable boat builder but I hear a lot of "good bones" stories. Four layers of fiberglass at hull to deck joint ..... sounds like renewed bones? It all starts with the hull but everything has to "stay" together. Aside from strengthening, any other considerations? Was this to lessen the condensation/weeping issue? Bow thrusters ..... another through the hull aperture ? Boat this size, this is a must ....... Stabilizers ..... Did you consider these? I don't like anything through the hull ... was this a consideration? How about holding tanks for sewerage? If you could, explain "Trinidad non ablative. New anodes of course?" If you have the time this winter and want to be more explicit about this incredible refit, an abbreviated thread would be most helpful. Yes, this story excites this one salt .....

So a good place to start might be with my boat selection process. I am a sailor at heart. Loved the rag blowers. Owned a motor sailer for many years until Hurricane Katrina blew it ashore. I always thought that I would retire young and my retirement years would be spent sailing a blow boat around the South Pacific as I had spent a lot of time in my early career as a deck officer on cargo ships wandering around the islands picking up coconuts. I just loved that part of the world. However my retirement years kept getting pushed back and I waited too long. I had a bout of pneumonia which was untreated (who goes to the doc just because of a persistent cough anyway?) and by the time I went to an ER three months later I had septicemia throughout my bloodstream and was dying. I was in the ER for four days before the could move me to intensive care. Anyways, thanks to good docs, I won that battle but it had weakened my heart and a month later I had a triple by-pass and five months after that I had five stents installed. Later I also had a pacemaker installed. To say that I was weakened was an understatement. I felt as strong as a wet rag.

I took a disability/retirement and set about reorganizing my life. Sold my plane and my condo. Decided to live aboard permanently. Now sailboats were out of the question due to physical limitations so I started to look at trawlers and motor yachts. With a budget of $250-300k I looked at a lot of boats. Since it was to be my home I wanted high quality and room to move around in. I thought that 45' to 55' would be the sweet spot that I can handle, solo if necessary. I was disappointed in a lot of the boats in the price range, they looked old or tired or needed some upgrading. Most smelled bad. The boats I did like we're outside my price range at $500k+. At that price range I would have little left to live on so they were disregarded.

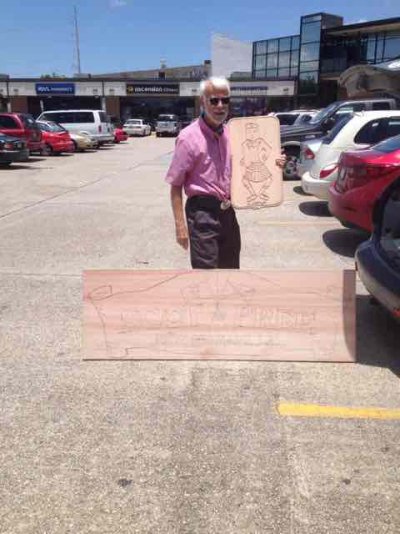

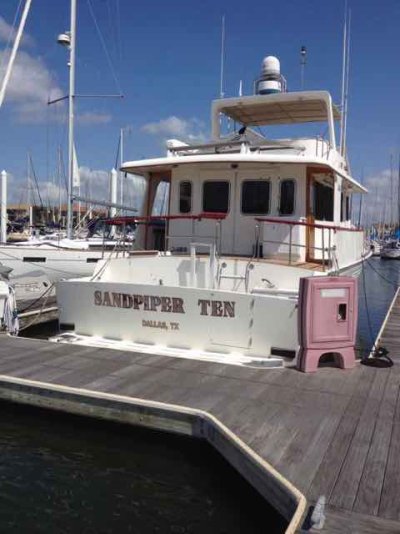

Eventually after about a year of looking, I came across Sandpiper 10 in Houston. The boat was a 1987 build and was in Houston. I called the broker and scheduled a visit. It was a second owner boat, the first being a dentist who used it in Florida and the Bahamas, the second being a gentleman from Dallas who moved it to Houston in about 2001 and had hardly used it since due to a series of life events and inconvenience. He had added only about 200 hours to it after it arrived in Houston. The inspection revealed that the coatings were chalky all over and were spider cracked on the upper and main decks. Wood trim on the hull was painted and bleeding rust. Interior furnishings were musty, faded and dated. Everything seemed to work though and I really liked the layout. The structure of the boat was hell for stout, the piping was copper nickel and the electrical was commercial grade well laid in proper conduit. On the upper deck was a jet ski that hadn't run in 10 years. The engine room was walk in with 6'6" headroom.

Both engines started at the touch of the starter buttons as did the generator. The generator looked brand new and had only 300 hours. The original had been a Westerbeke and had been replaced with this Northern Lights. There was a Village Marine water maker installed that had been pickled after installation and never run. Everything seemed to operate as designed.

So rather than find a boat in walk on condition that suited me, I decided that here was a boat that could be refit to suit me. It had been on the market for about a year due to its poor cosmetic condition. It was already a low price for its type. I offered $50k less than asking and it was accepted, as is where is. I did have the opportunity to make it subject to survey which I did with both a hull surveyor and a machinery surveyor. (Note, I did this even though I had been a professional commercial marine surveyor for well over 20 years, certified by NAMS and was in fact the National Secretary for NAMS at the time.) At closing the seller had to come up with 20k to pay off his bank loan. I felt sorry for him but he made up for it by being a bit of a jerk and not answering any of my questions about the boat and walking away as soon as the paperwork was signed without looking back. So I had to figure out all the systems on the boat by myself which happens to be a bit of a chore and something to keep in mind when you buy a boat..

Some specs on the boat according to the broker:

Make: Cheoy Lee Efficient Cockpit Motor Yacht

Length 52'. Breadth 16'. Draft 4'5"

Engines: 2 x Caterpillar model 3208 TA rated at 320 hp each

Fuel: 1,000 us gallons

Fresh Water: 450 gallons

Holding Tank: 40 gallons.

3 Cabins

2 Heads

Bridge Clearance: 24'

Cruising Speed 12 knots @ 1800 rpm

Max Speed 16.5 knots

Range 1,700 nm.

More to come.

Sent from my iPad using Trawler Forum

McGill; This is incredibly helpful and it sounds like you got good value for the $$ spent. With the exception of the mechanicals, sounds like you took almost everything down to bear hull and did the cosmatics. I'm sure she looks incredible!! I'm keeping your list as I feel I could be facing a similar situation. How much work did you do yourself? Sounds like you did a lot -- a lot. For that money and what you did - a lot! I like all of your ideas including the Capt's gig ...... very cool for those shallow inlets. You obviously picked a yard to have some of the work done ..... what were the considerations for that choice? Did you live abroad during the dry dock/refit? You've got a great eye for customizing. When you say "good bones" can you be more explicit? Choey Lee is a reputable boat builder but I hear a lot of "good bones" stories. Four layers of fiberglass at hull to deck joint ..... sounds like renewed bones? It all starts with the hull but everything has to "stay" together. Aside from strengthening, any other considerations? Was this to lessen the condensation/weeping issue? Bow thrusters ..... another through the hull aperture ? Boat this size, this is a must ....... Stabilizers ..... Did you consider these? I don't like anything through the hull ... was this a consideration? How about holding tanks for sewerage? If you could, explain "Trinidad non ablative. New anodes of course?" If you have the time this winter and want to be more explicit about this incredible refit, an abbreviated thread would be most helpful. Yes, this story excites this one salt .....

So a good place to start might be with my boat selection process. I am a sailor at heart. Loved the rag blowers. Owned a motor sailer for many years until Hurricane Katrina blew it ashore. I always thought that I would retire young and my retirement years would be spent sailing a blow boat around the South Pacific as I had spent a lot of time in my early career as a deck officer on cargo ships wandering around the islands picking up coconuts. I just loved that part of the world. However my retirement years kept getting pushed back and I waited too long. I had a bout of pneumonia which was untreated (who goes to the doc just because of a persistent cough anyway?) and by the time I went to an ER three months later I had septicemia throughout my bloodstream and was dying. I was in the ER for four days before the could move me to intensive care. Anyways, thanks to good docs, I won that battle but it had weakened my heart and a month later I had a triple by-pass and five months after that I had five stents installed. Later I also had a pacemaker installed. To say that I was weakened was an understatement. I felt as strong as a wet rag.

I took a disability/retirement and set about reorganizing my life. Sold my plane and my condo. Decided to live aboard permanently. Now sailboats were out of the question due to physical limitations so I started to look at trawlers and motor yachts. With a budget of $250-300k I looked at a lot of boats. Since it was to be my home I wanted high quality and room to move around in. I thought that 45' to 55' would be the sweet spot that I can handle, solo if necessary. I was disappointed in a lot of the boats in the price range, they looked old or tired or needed some upgrading. Most smelled bad. The boats I did like we're outside my price range at $500k+. At that price range I would have little left to live on so they were disregarded.

Eventually after about a year of looking, I came across Sandpiper 10 in Houston. The boat was a 1987 build and was in Houston. I called the broker and scheduled a visit. It was a second owner boat, the first being a dentist who used it in Florida and the Bahamas, the second being a gentleman from Dallas who moved it to Houston in about 2001 and had hardly used it since due to a series of life events and inconvenience. He had added only about 200 hours to it after it arrived in Houston. The inspection revealed that the coatings were chalky all over and were spider cracked on the upper and main decks. Wood trim on the hull was painted and bleeding rust. Interior furnishings were musty, faded and dated. Everything seemed to work though and I really liked the layout. The structure of the boat was hell for stout, the piping was copper nickel and the electrical was commercial grade well laid in proper conduit. On the upper deck was a jet ski that hadn't run in 10 years. The engine room was walk in with 6'6" headroom.

Both engines started at the touch of the starter buttons as did the generator. The generator looked brand new and had only 300 hours. The original had been a Westerbeke and had been replaced with this Northern Lights. There was a Village Marine water maker installed that had been pickled after installation and never run. Everything seemed to operate as designed.

So rather than find a boat in walk on condition that suited me, I decided that here was a boat that could be refit to suit me. It had been on the market for about a year due to its poor cosmetic condition. It was already a low price for its type. I offered $50k less than asking and it was accepted, as is where is. I did have the opportunity to make it subject to survey which I did with both a hull surveyor and a machinery surveyor. (Note, I did this even though I had been a professional commercial marine surveyor for well over 20 years, certified by NAMS and was in fact the National Secretary for NAMS at the time.) At closing the seller had to come up with 20k to pay off his bank loan. I felt sorry for him but he made up for it by being a bit of a jerk and not answering any of my questions about the boat and walking away as soon as the paperwork was signed without looking back. So I had to figure out all the systems on the boat by myself which happens to be a bit of a chore and something to keep in mind when you buy a boat..

Some specs on the boat according to the broker:

Make: Cheoy Lee Efficient Cockpit Motor Yacht

Length 52'. Breadth 16'. Draft 4'5"

Engines: 2 x Caterpillar model 3208 TA rated at 320 hp each

Fuel: 1,000 us gallons

Fresh Water: 450 gallons

Holding Tank: 40 gallons.

3 Cabins

2 Heads

Bridge Clearance: 24'

Cruising Speed 12 knots @ 1800 rpm

Max Speed 16.5 knots

Range 1,700 nm.

More to come.

Sent from my iPad using Trawler Forum