FOG

Guru

We recently purchased a 1981 Prairie 36 to do the Great Loop in 2017 and other East Coast cruising. In addition to our first improvement, a mattress for the Aft State Room, which you can read about in this thread http://www.trawlerforum.com/forums/s34/prairie-36-offer-24354.html

We have a laundry list of other ideas.

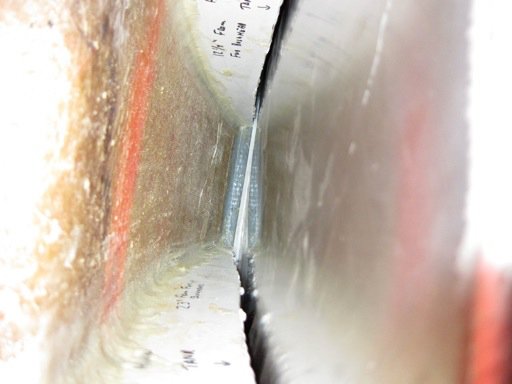

First up is a better anchoring system. So our first big purchase was a new windlass and a used anchor. The old anchor was too small and the windlass works but will only bring the anchor up. I also want to be able to remotely operate the windlass from either helm position. Dropping the anchor must be done manually by hand, no motor down or free fall on the old windlass. Even raising the anchor requires hand feeding the chain/rode down the hawse pipe, see the picture.

My current thought is to mount the new windlass on top of the bowsprit/pulpit so there will be a straight drop to the bottom of the chain locker creating a nice pile.

I'd like some feedback on this idea and thoughts on how your windlass and anchoring systems are set up. What anchoring system works best for you?

We have a laundry list of other ideas.

First up is a better anchoring system. So our first big purchase was a new windlass and a used anchor. The old anchor was too small and the windlass works but will only bring the anchor up. I also want to be able to remotely operate the windlass from either helm position. Dropping the anchor must be done manually by hand, no motor down or free fall on the old windlass. Even raising the anchor requires hand feeding the chain/rode down the hawse pipe, see the picture.

My current thought is to mount the new windlass on top of the bowsprit/pulpit so there will be a straight drop to the bottom of the chain locker creating a nice pile.

I'd like some feedback on this idea and thoughts on how your windlass and anchoring systems are set up. What anchoring system works best for you?

Attachments

Last edited:

or

or