I am starting this thread to hopefully attract some Mainship Yahoo forum members and others who have had turbo freezing problems, probably caused by sea water backing up into the exhaust. I have several solutions to offer and will discuss these in this thread once a few Mainship guys have joined this discussion from the Yahoo forum.

I will start the ball rolling by discussing turbo failures and the generally accepted criteria for a fail safe exhaust system design. Please refer to the attached drawing and pics.

Turbos usually don't fail by themselves. Over the road turbos on diesels last for hundreds of thousands of miles. When a marine turbo fails after a a thousand hours, it is almost always caused by something other than the turbo just crapping out by itself.

The most common cause is sea water backing up into the exhaust turbo throat. This occurs after the engine is shut down and waves hit the transom, forcing a slug of water up into the exhaust, over the riser and into the turbo.

A second cause is mixer failure due to poor design which lets water sit in the mixer until it corrodes through the interior metal and then down into the turbo.

Turbo symptoms of this effect are poor performance, usually low power and lots of black smoke. This often means that the turbo is stuck and won't turn. Sometimes the turbo will spin freely but won't perform well because of the blade tip to housing dimension being corroded out.

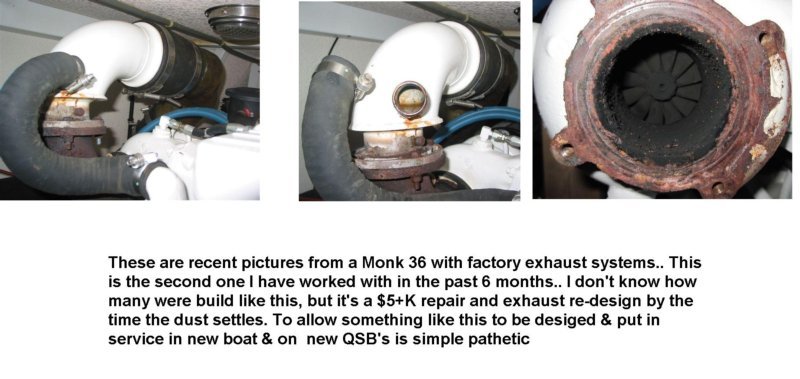

Take the exhaust riser off of your turbo and look inside. If it has heavy flaky corrosion and if the blade tip to housing dimension is greater than 0.030" then you have had water getting in. If your mixer doesn't self drain like the pic, below then you will soon have a problem. Also take a look at the turbo exaust throat and the extensive corrosion.

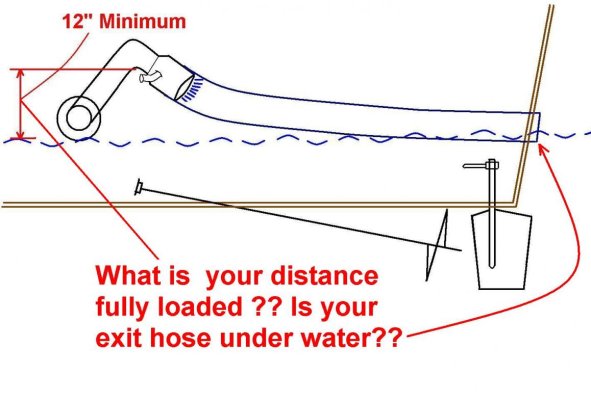

As you can see from the next pic, a good marine exhaust system should have the riser go up at least 12" above the water line. It should also have the mixer pointed downward so it will self drain after the engine shuts down. Otherwise a pool of water will sit in the mixer, corrode it and then flow back into the turbo.

The pictures are courtesy of Tony Athens, the moderator of boatdiesel.com and a crusader for good exhaust system design.

More to come.

David

I will start the ball rolling by discussing turbo failures and the generally accepted criteria for a fail safe exhaust system design. Please refer to the attached drawing and pics.

Turbos usually don't fail by themselves. Over the road turbos on diesels last for hundreds of thousands of miles. When a marine turbo fails after a a thousand hours, it is almost always caused by something other than the turbo just crapping out by itself.

The most common cause is sea water backing up into the exhaust turbo throat. This occurs after the engine is shut down and waves hit the transom, forcing a slug of water up into the exhaust, over the riser and into the turbo.

A second cause is mixer failure due to poor design which lets water sit in the mixer until it corrodes through the interior metal and then down into the turbo.

Turbo symptoms of this effect are poor performance, usually low power and lots of black smoke. This often means that the turbo is stuck and won't turn. Sometimes the turbo will spin freely but won't perform well because of the blade tip to housing dimension being corroded out.

Take the exhaust riser off of your turbo and look inside. If it has heavy flaky corrosion and if the blade tip to housing dimension is greater than 0.030" then you have had water getting in. If your mixer doesn't self drain like the pic, below then you will soon have a problem. Also take a look at the turbo exaust throat and the extensive corrosion.

As you can see from the next pic, a good marine exhaust system should have the riser go up at least 12" above the water line. It should also have the mixer pointed downward so it will self drain after the engine shuts down. Otherwise a pool of water will sit in the mixer, corrode it and then flow back into the turbo.

The pictures are courtesy of Tony Athens, the moderator of boatdiesel.com and a crusader for good exhaust system design.

More to come.

David

Attachments

Last edited: