Dune

Senior Member

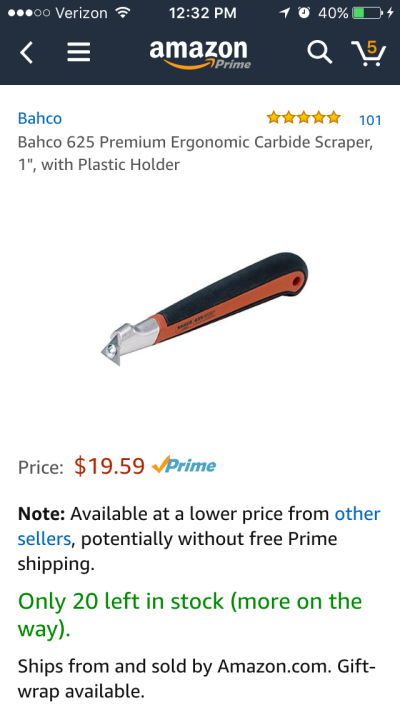

In other words, for enlarging and cleaning out a minor gelcoat crack prior to Marinetex application. A V can opener end works of course but seems like there would be something of harder alloy and sharper....or maybe even electric ?

Also....never tried it, but wondering if there exists a masking tape one could apply over a minor crack and then V scrape the crack out by feel, so that only the crack is exposed which would make Marinetex application less messy.

To be sure you weren't scratching out anywhere other than the crack perhaps go over the tape first with sharp knife to create a target path ?

Seems like regular masking tape might fray too much. But perhaps not, if one had a super sharp V scraper ?

Thoughts ?

(And please try to resist comments about first finding the reason for the cracks as I am well aware of that aspect and in this thread rather discuss cosmetic crack repair techniques)

Also....never tried it, but wondering if there exists a masking tape one could apply over a minor crack and then V scrape the crack out by feel, so that only the crack is exposed which would make Marinetex application less messy.

To be sure you weren't scratching out anywhere other than the crack perhaps go over the tape first with sharp knife to create a target path ?

Seems like regular masking tape might fray too much. But perhaps not, if one had a super sharp V scraper ?

Thoughts ?

(And please try to resist comments about first finding the reason for the cracks as I am well aware of that aspect and in this thread rather discuss cosmetic crack repair techniques)

What they said. When we repainted/new gel-coat, we couldn't have done it with out the Dremel. Fast and easy to control plus cracks aren't always in a straight line.

What they said. When we repainted/new gel-coat, we couldn't have done it with out the Dremel. Fast and easy to control plus cracks aren't always in a straight line.