Dave;

I think your question was a good one but maybe buried too deep in the haystack so here's a boost...

I think your question was a good one but maybe buried too deep in the haystack so here's a boost...

I was looking at my genny primary fuel filter to change it. I started looking for fuel shut off valve to the filter and could find one. The level of the filter is lower than the level of the fuel in the tank. I think that if I remove the filter, that level will equalize and I will have 20-50 gallons of fuel in my bilge. That doesn't sound like a good idea.

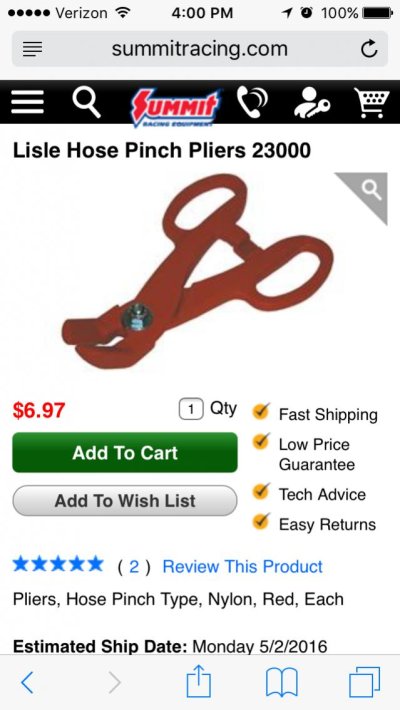

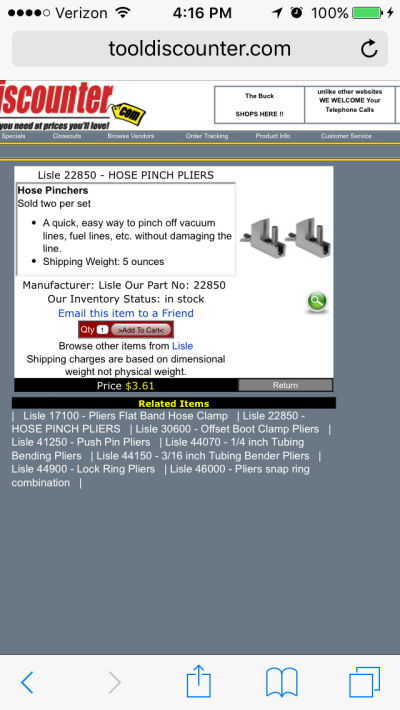

Here is the fuel filter.