As my shipyard and I are finalizing the design of a new trawler (displacement, not SD), I've had occasion to reflect and argue with friends about the total power for the boat.

Hull speed typically requires about 3.8 - 4.5 hp/long ton, but it seems the current trend is for even higher ratios.

Some factors that would affect this are:

My decision to power at 3.2 hp/ton was based on the following:

It would be interesting to see how other cruisers power their boats, or would power their boats if they could swap out engines.

Hull speed typically requires about 3.8 - 4.5 hp/long ton, but it seems the current trend is for even higher ratios.

Some factors that would affect this are:

- How efficient the hullform (fat versus skinny)

- Windage

- Reserve power needed to suit cruising conditions/currents often encountered

- Personal preference

- Budget

My decision to power at 3.2 hp/ton was based on the following:

- Fat, deep hull form - It is less efficient, so this is opposite to my decision

- Very low frontal windage and side windage (A/B ratio = 1.85)

- "Normal" cruising conditions - I've had little need for a lot of reserve power in the past

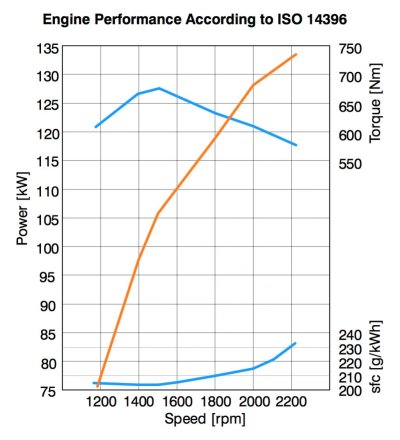

- I'll be running my engine at 80% (1500 rpm), coinciding with maximum torque and fuel efficiency (22 hp/gal-hr)

- Need to keep expenses within reason and don't want to overpower

It would be interesting to see how other cruisers power their boats, or would power their boats if they could swap out engines.