MurrayM

Guru

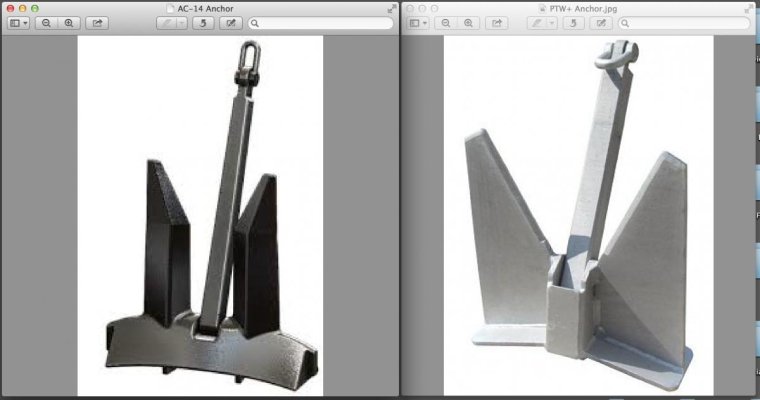

My gift to Eric and the forum is a new anchor to discuss

The Posidonia PTW+® Anchor, the first stockless anchor to be rated by Lloyds as super high holding power;

POSIDONIA SRL - Products > Anchors > Yacht anchors > PTW+ Anchors

Italian made, comes in sizes down to 17kg (pretty suspect at that size I bet) but would look pretty damn cool snuggled up against the bow through the hawse pipe of a medium to large sized trawler...

The Posidonia PTW+® Anchor, the first stockless anchor to be rated by Lloyds as super high holding power;

POSIDONIA SRL - Products > Anchors > Yacht anchors > PTW+ Anchors

Italian made, comes in sizes down to 17kg (pretty suspect at that size I bet) but would look pretty damn cool snuggled up against the bow through the hawse pipe of a medium to large sized trawler...

Attachments

Last edited: