R_p_ryan

Senior Member

- Joined

- Dec 11, 2014

- Messages

- 171

- Location

- USA

- Vessel Name

- Shellbourne

- Vessel Make

- 1978 Mainship 34 Perkins T6.354

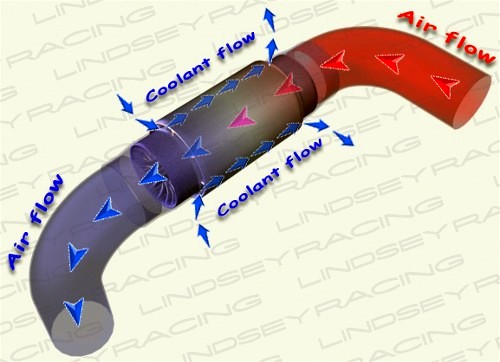

Is there any reason why a low cost titanium shell and tube heat exchanger should not be used to cool a marine diesel? These units are primarily for salt water pools with chlorine but they state they can be used for marine cooling, including oil and salt water. https://www.brazetek.com/bt-stx-85-2-titanium-heat-exchanger

At $380 and considering its titanium it seems like an ideal substitute. But there's little info online of any marine experience with them, except an old study by the navy on titanium fouling with growth at low temperatures.

My air charge cooler is an old Bowman unit with a cast iron sleeve that is raw water cooled and was very badly corroded on the inside. I could imagine the engine vibrations could be a factor with a lightweight cooler like the one above.

Thanks,

Robert.

At $380 and considering its titanium it seems like an ideal substitute. But there's little info online of any marine experience with them, except an old study by the navy on titanium fouling with growth at low temperatures.

My air charge cooler is an old Bowman unit with a cast iron sleeve that is raw water cooled and was very badly corroded on the inside. I could imagine the engine vibrations could be a factor with a lightweight cooler like the one above.

Thanks,

Robert.