We watched a brand new Sunbrella full boat cover on a 40' Cheoy Lee sailboat completely destroy itself during its first winter. The boat shared our slip and the owner lived and worked in SoCal. We get some pretty nasty storms marching through the bay where we keep our boat with gusts that have been clocked as high as 80mph by the weather station on top of the cold storage facility in our harbor.

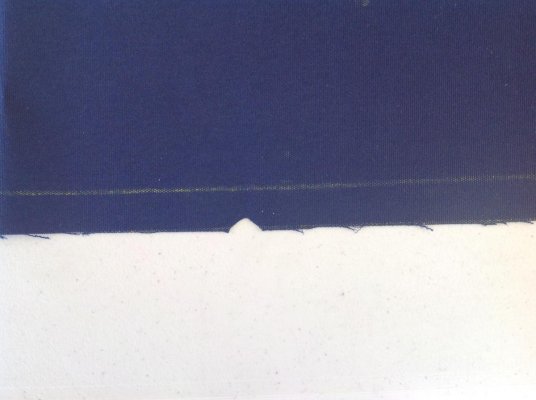

The problem started with a single seam that let go along less than six inches of its length. We immediately reported this to the port and they contacted the owner but he apparently didn't want to do anything about it.

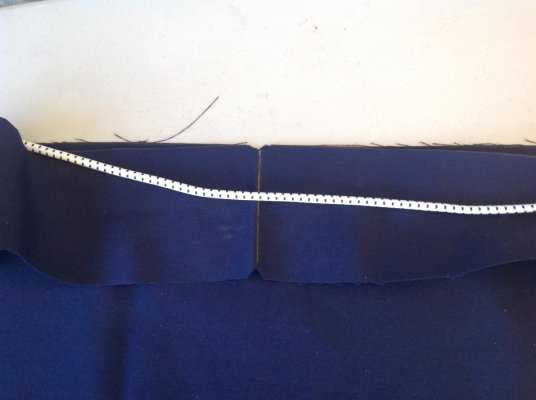

The constant flapping soon tore the seam out along its entire length and as the flapping got worse more seams began to tear out. The port continued to contact the owner who continued to not want to do anything about it despite his son living in the same town as the boat.

Within about two months or so the cover was a total wreck with half of it trailing off the boat into the water. At that point the port removed the whole thing as a hazard and threw it all in a dumpster.

This all started with the thread letting go along a tiny section of seam.

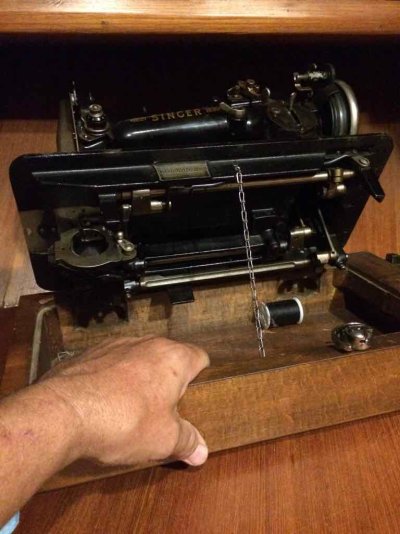

I have no idea of the quality of the cover. It certainly looked nice when the guys who brought the boat over from its previous slip put it on. But it obviously was made with inferior materials, workmanship, or both as our ancient, two-part full flying bridge cover, which was old when we bought the boat 17 years ago, has continued to hold through winter after winter, due totally to my wife's efforts at re-sewing seams, installing patches, and so on. If it lasts this winter we'll be amazed, and my wife is already contemplating the process of making a brand new one next year.

If you can get the seams to hold, it's surprising how long the canvas itself will hold up.