Brisyboy

Senior Member

- Joined

- Mar 7, 2015

- Messages

- 423

- Location

- Australia

- Vessel Name

- Malagari

- Vessel Make

- Island Gypsy 36 Europa

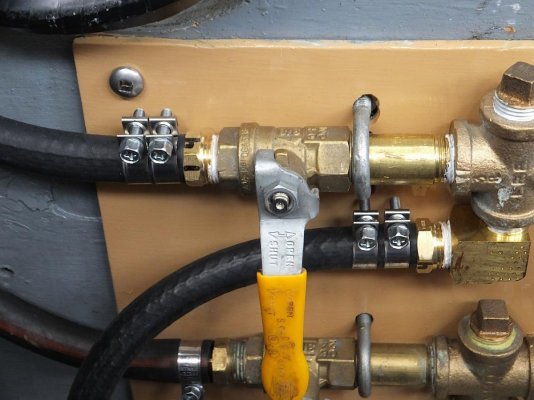

Just going through all the inlet/discharge hoses on our new to us boat and wondering what is the normal practice for double clamping ie two hose clamps rather than the normal one. - just those below the waterline? all inlets - is there a rule of thumb.

BTW, I intend using 316 Norma clamps - good enough - or is there a better option?

cheers

George

BTW, I intend using 316 Norma clamps - good enough - or is there a better option?

cheers

George

[/URL

[/URL