sailtones

Veteran Member

- Joined

- Jan 22, 2013

- Messages

- 97

- Location

- Montenegro

- Vessel Name

- Nostra Signora

- Vessel Make

- Marine Trader CHB 34DC

Okay so this will be a fairly long description of a current job that I hope may be of use to someone who may experience the same thing and need advice.

During the original survey of the boat, we realized that the starboard salon sliding window had some leakage issues. The water was finding its way inside the core of the cabin just under the aft lower end of the window and starting to damage the teak veneer on the interior under the window.

I finally got around to investigating the issue fully the other day.

Before I started the job, I researched online to see if anyone else had undertaken this repair and posted their findings. Chuck from Beach house had taken apart one of his windows in a similar way, but his repair was not done one of the sliding windows.

So I have decided to write it up so that anyone else who has this problem, can find some insight prior to taking on the job.

First off I started some unobtrusive investigation to see if I could effect a repair that would not require me to dismantle the entire window. Unfortunately I couldn't really see much beyond the 30 odd years of sealant that had been used with wanton abandon by the previous owners attempt to solve what was obviously an ongoing issue. Finally I decided to undertake proper and permanent repair so that I will never have to think about this one again.

The only way forward was to take off the teak trim, take out the window and have a proper look. Given that the teak trim was not in very good shape, I also made the decision to replace it rather than try to save it. This allowed me to be a little more forceful in the removal of the trim.

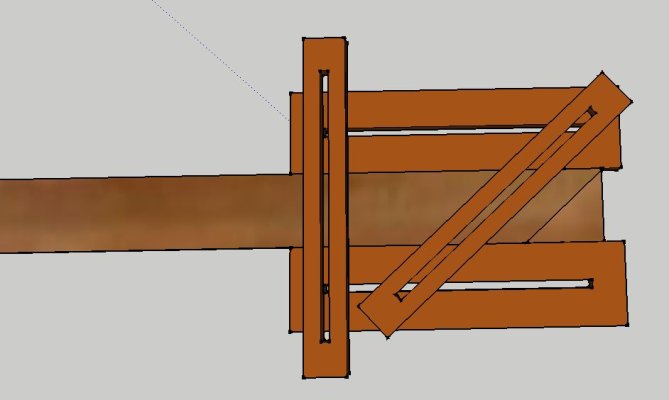

Once the trim was off, the window was out, and the random ply spacers whose purpose was to space out the ill-fitting glass (I assume they must have ordered loads of glass for the production line of these boats, and fitted it as best they could on each boat with packers and spacers) had been removed from around the glass, I could clearly see that the core of the cabin side had not been sealed other than with the bedding compound of the sliding window track. Over the years the compound (and track) had failed allowing water to enter the core, thus resulting in the damage seen to the interior woodwork.

During the original survey of the boat, we realized that the starboard salon sliding window had some leakage issues. The water was finding its way inside the core of the cabin just under the aft lower end of the window and starting to damage the teak veneer on the interior under the window.

I finally got around to investigating the issue fully the other day.

Before I started the job, I researched online to see if anyone else had undertaken this repair and posted their findings. Chuck from Beach house had taken apart one of his windows in a similar way, but his repair was not done one of the sliding windows.

So I have decided to write it up so that anyone else who has this problem, can find some insight prior to taking on the job.

First off I started some unobtrusive investigation to see if I could effect a repair that would not require me to dismantle the entire window. Unfortunately I couldn't really see much beyond the 30 odd years of sealant that had been used with wanton abandon by the previous owners attempt to solve what was obviously an ongoing issue. Finally I decided to undertake proper and permanent repair so that I will never have to think about this one again.

The only way forward was to take off the teak trim, take out the window and have a proper look. Given that the teak trim was not in very good shape, I also made the decision to replace it rather than try to save it. This allowed me to be a little more forceful in the removal of the trim.

Once the trim was off, the window was out, and the random ply spacers whose purpose was to space out the ill-fitting glass (I assume they must have ordered loads of glass for the production line of these boats, and fitted it as best they could on each boat with packers and spacers) had been removed from around the glass, I could clearly see that the core of the cabin side had not been sealed other than with the bedding compound of the sliding window track. Over the years the compound (and track) had failed allowing water to enter the core, thus resulting in the damage seen to the interior woodwork.

Attachments

Last edited: