healhustler mentioned in my Gig Harbor thread that he was happy to see a profile picture of Refugio. While I think my boat is interesting, I don't generally share much about it - mostly because it's ferro-cement and I have the suspicion that most people just won't "get it".

Though I've owned Refugio for more than 10 years, I don't have that many pictures - but here's one from Thetis Island last summer:

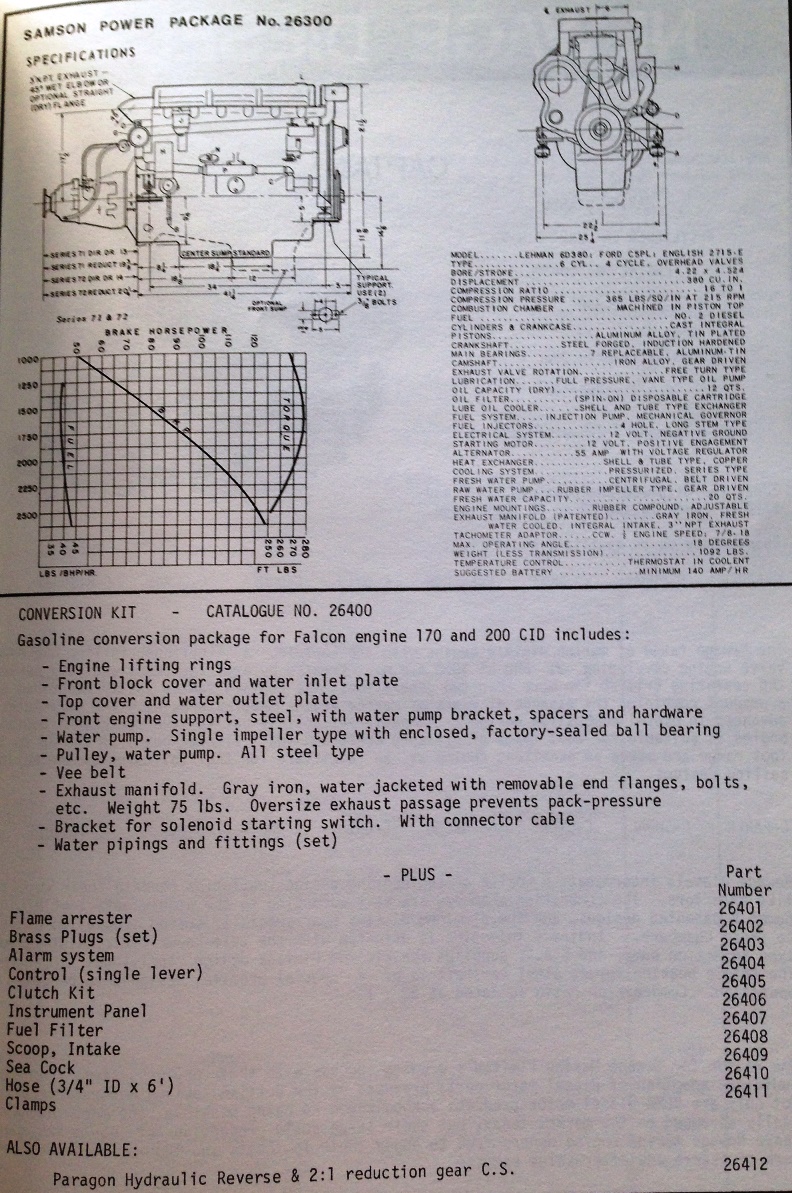

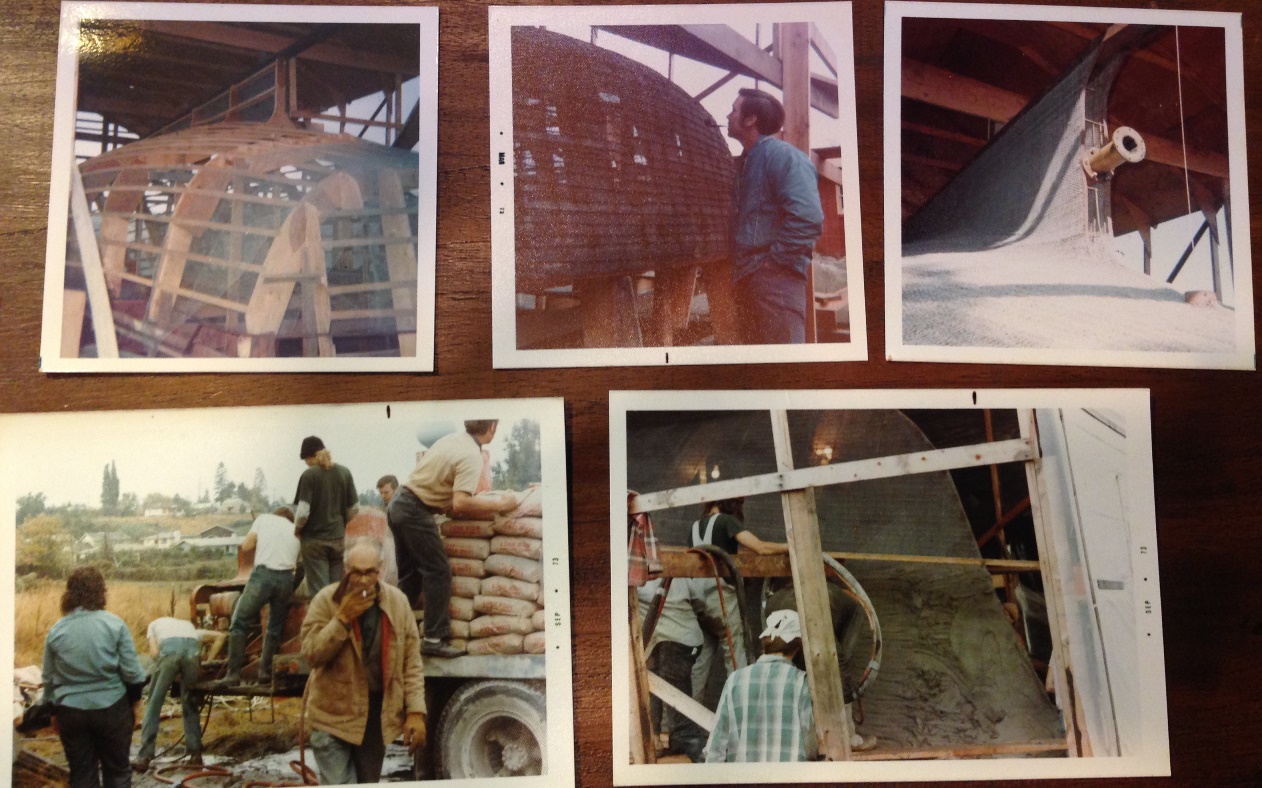

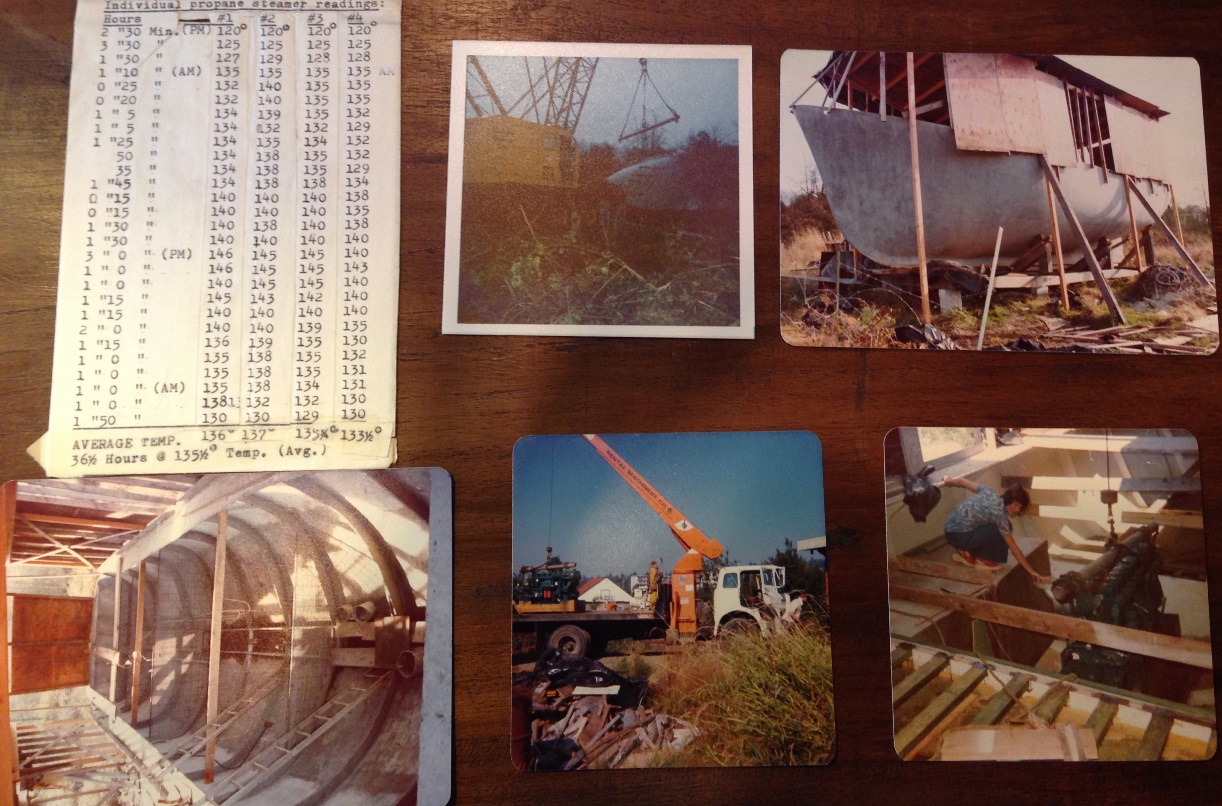

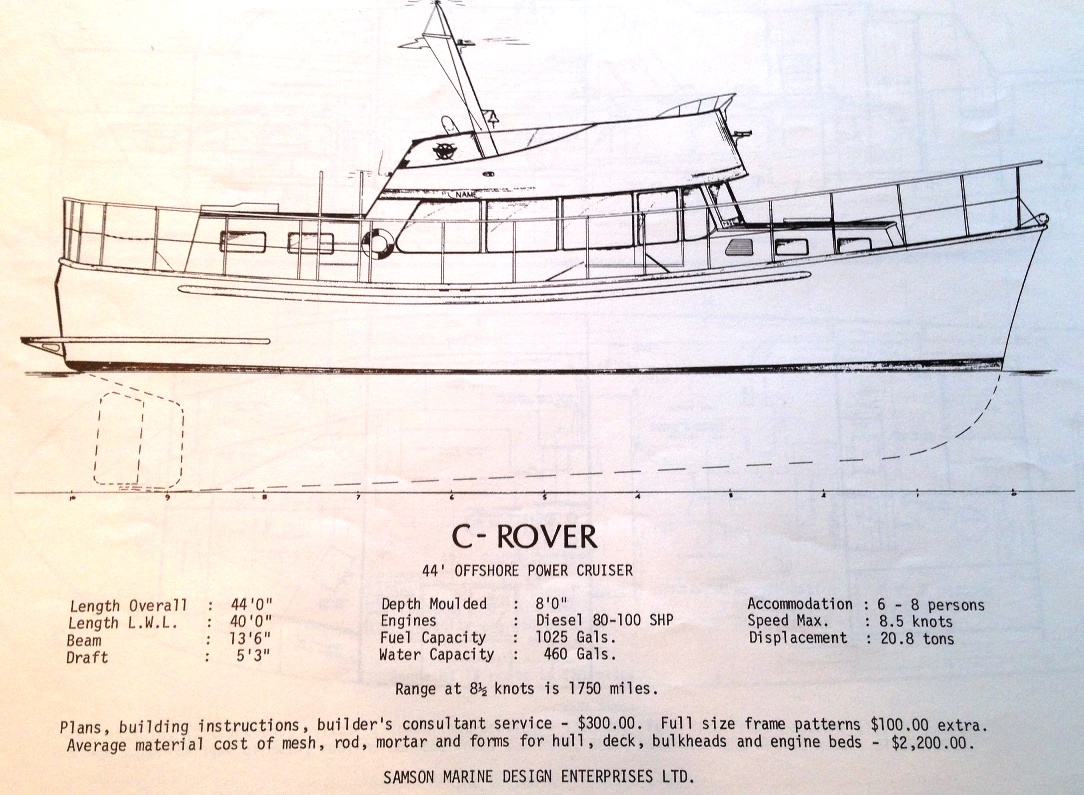

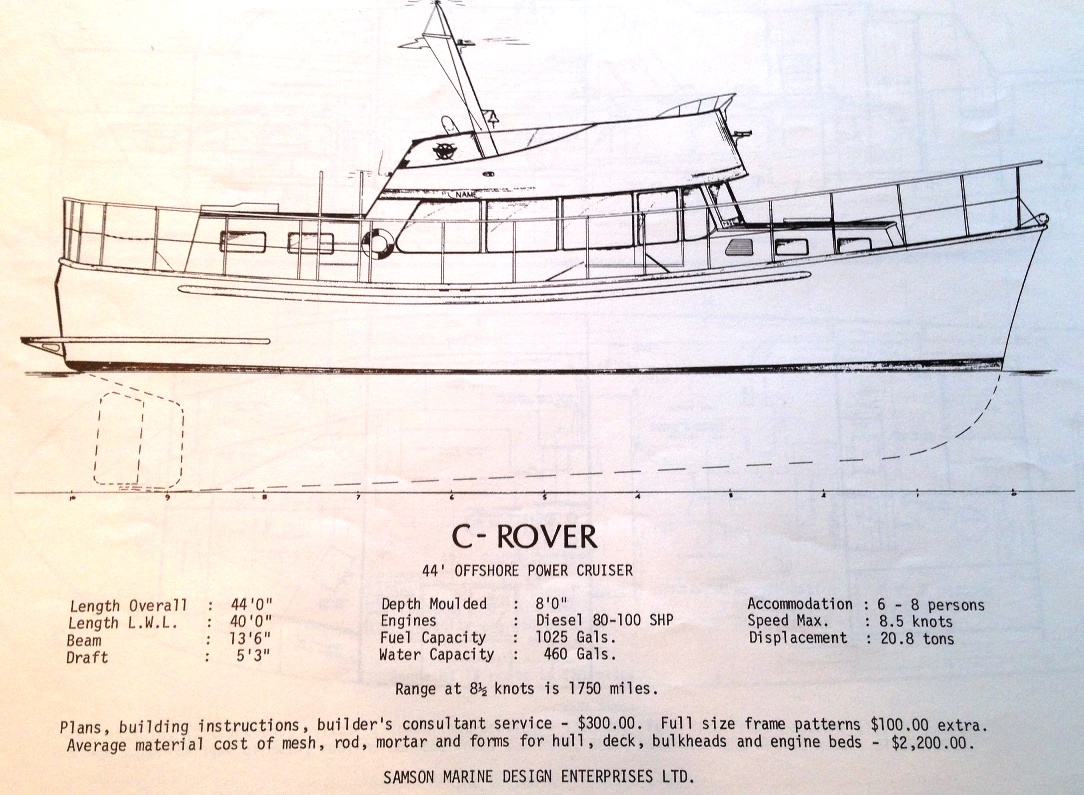

My boat's hull is a modified version of the Samson C-Rover:

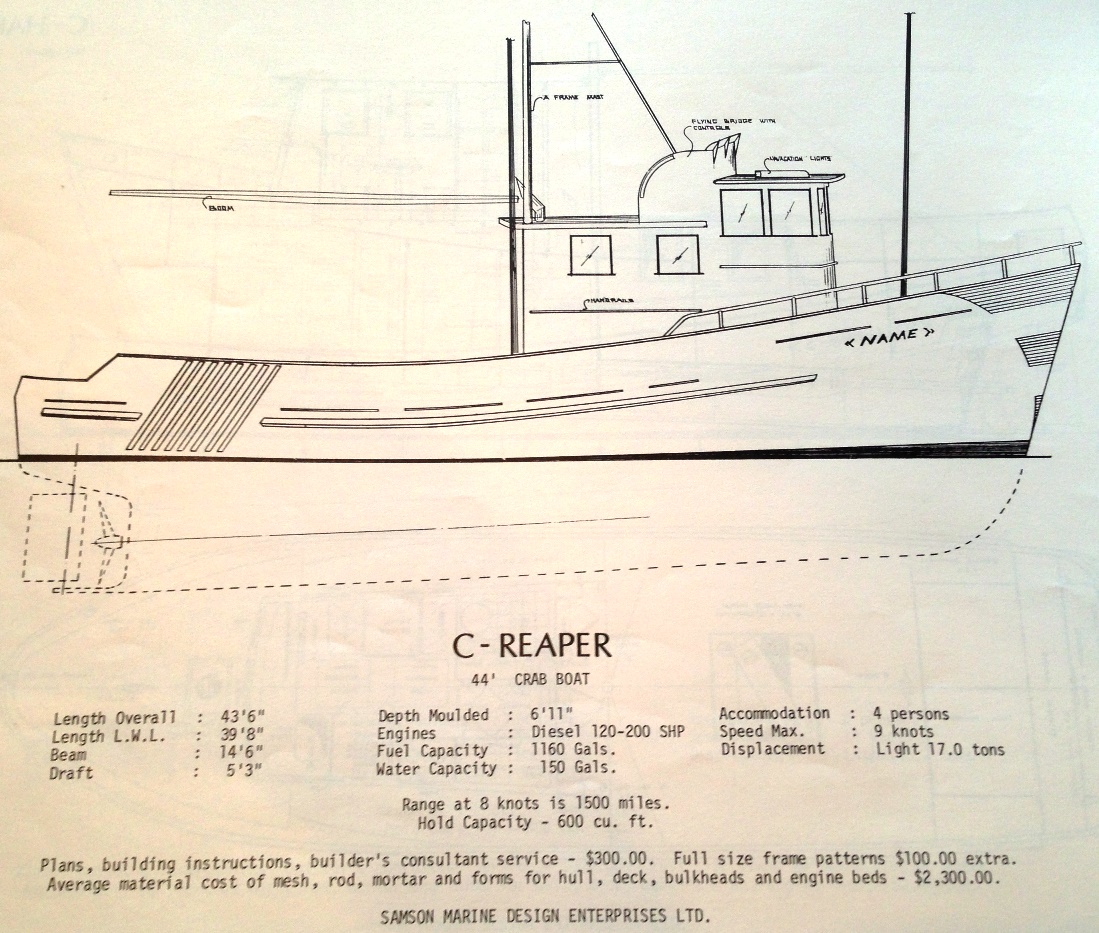

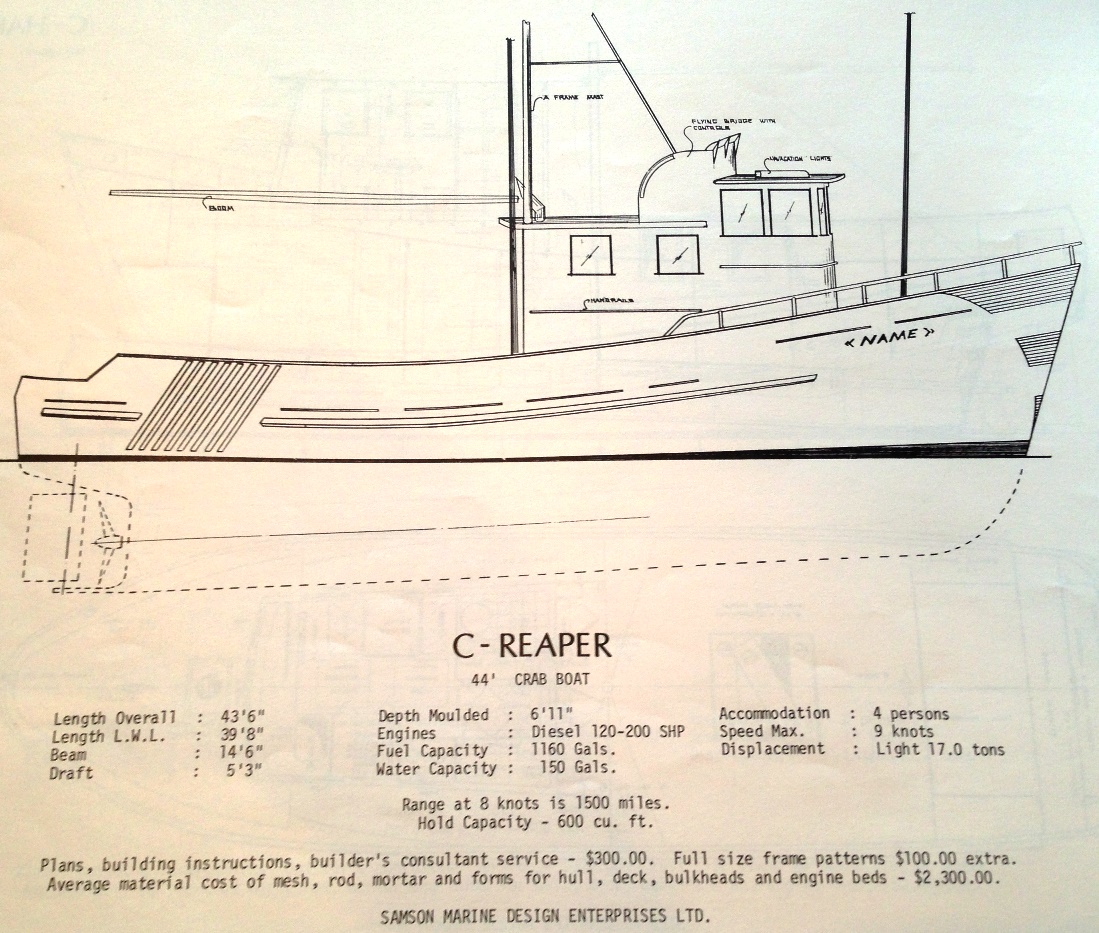

In particular, it has a fishing cockpit similar to the C-Reaper combined with a substantial bulwark forward that extends above the deck:

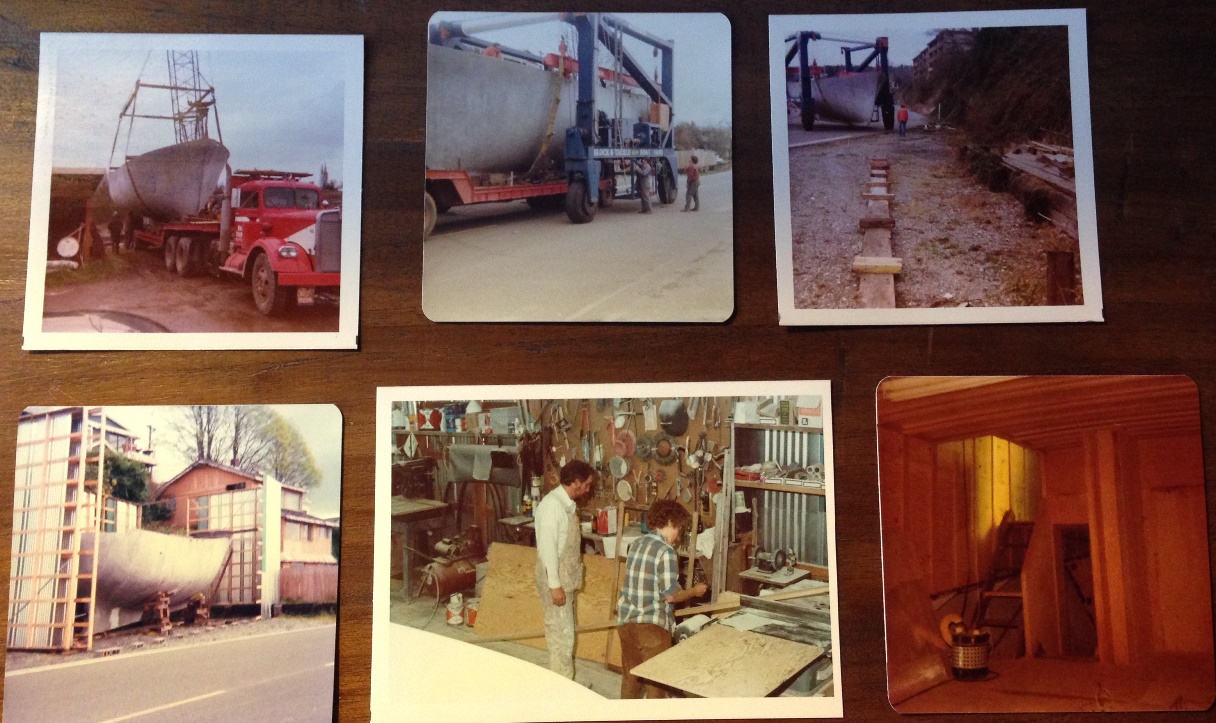

The builder had plans of fishing the boat - hence the cockpit, a huge insulated fish hold, and even an ice flaking machine. And the trolling valve that I use on occasion. The builder did many things right - 1100 gallons of fuel in 4 insulated fiberglass tanks, very skookum running gear, all Diamond Sea Glaze windows - and many things that are truly mediocre - wiring and plumbing in particular. He died soon after launching the boat, which was then bought as a liveaboard by a lady psychologist who removed all of the electronics, dinghy davit, etc. and installed house-sized kitchen appliances. Full-size fridge, electric range, trash compactor, disposal - even separate water heaters for the head and galley. I bought it from her, and I still have the disposal - very handy for transforming 30 pounds of garbage into 30 pounds of smaller garbage.

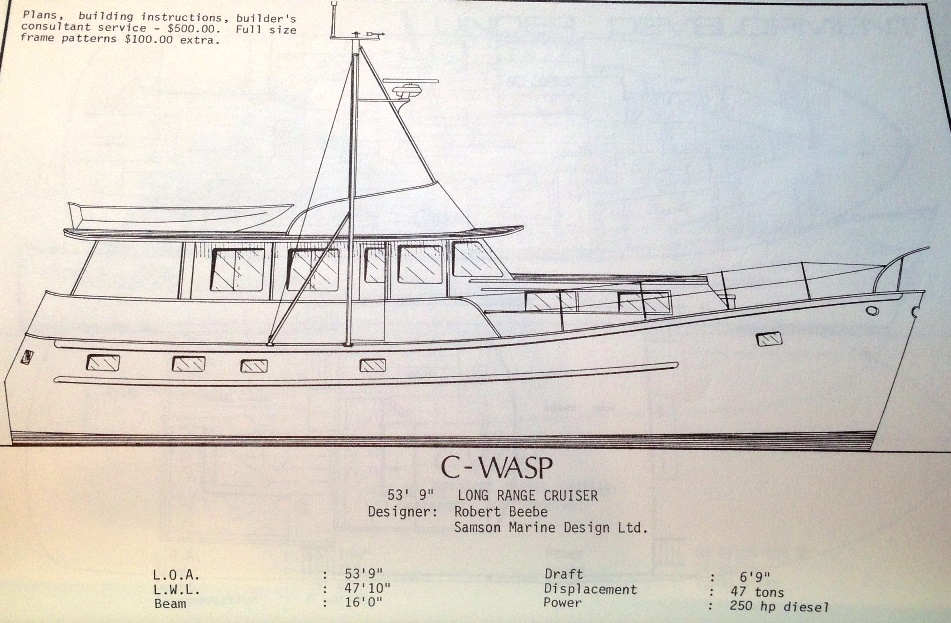

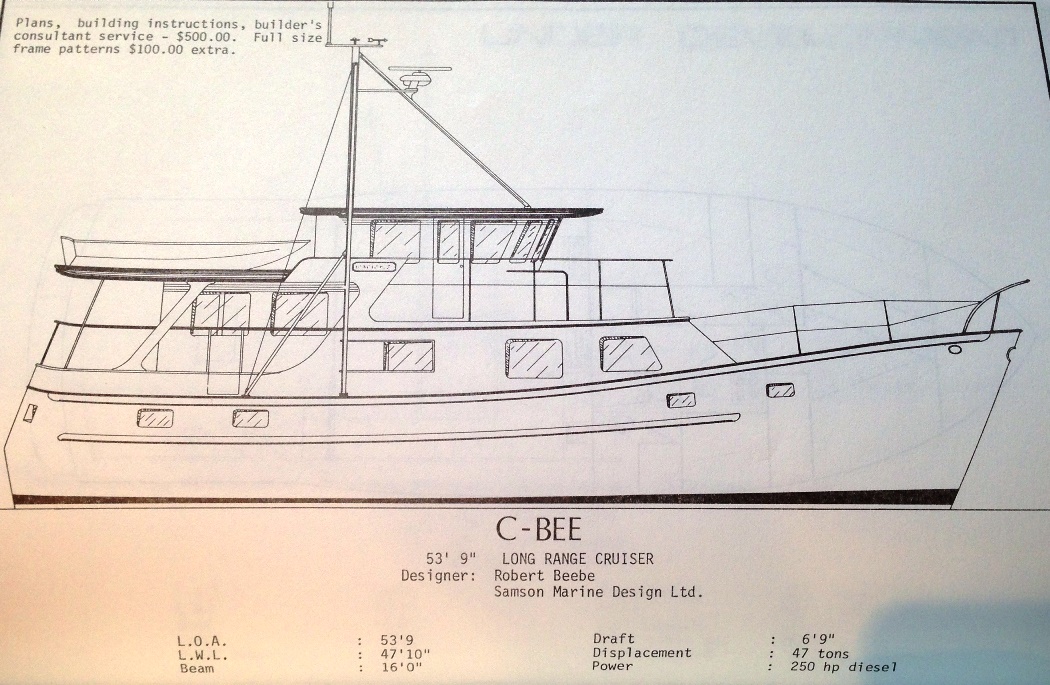

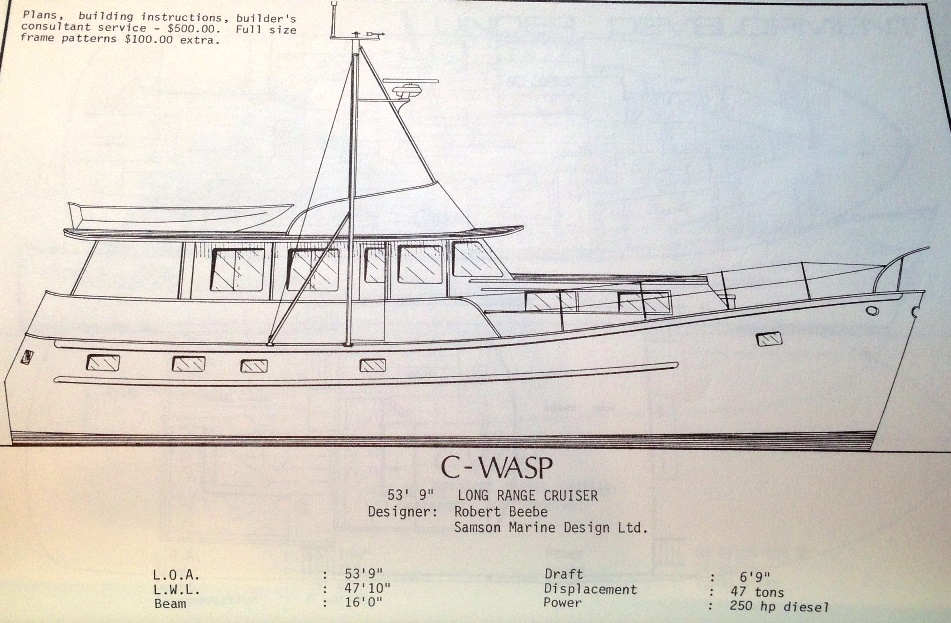

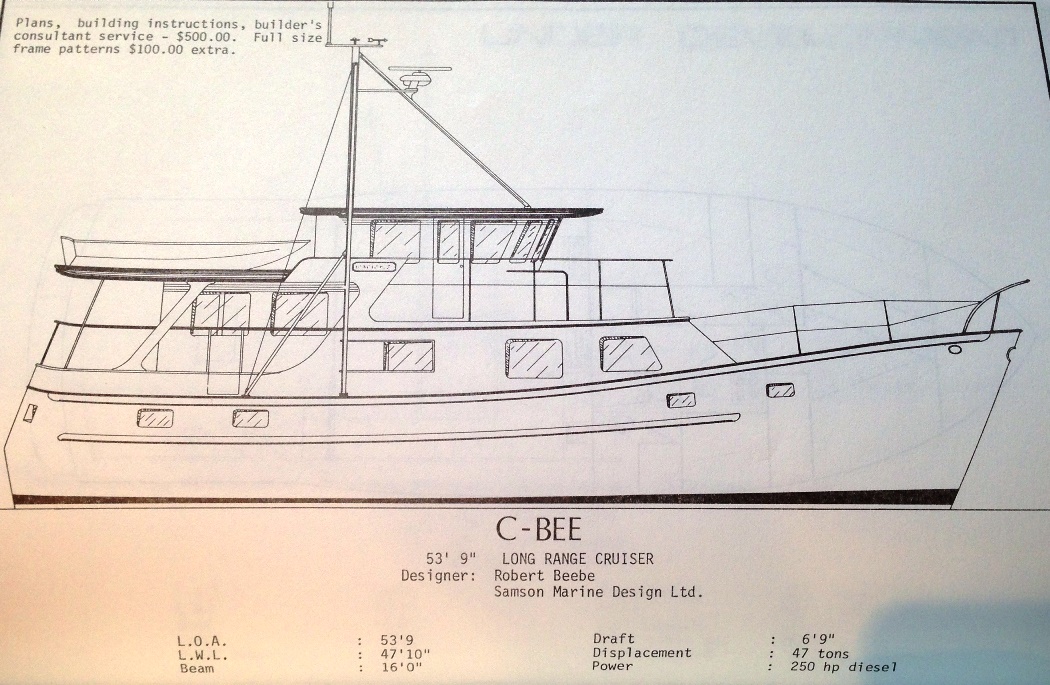

As I think everyone's aware, ferro-cement didn't survive in North America, though it's still thriving on a small scale in NZ and Australia. But back in the 70s it held great promise - here are a couple of designs by someone I think everyone's heard of:

Though I've owned Refugio for more than 10 years, I don't have that many pictures - but here's one from Thetis Island last summer:

My boat's hull is a modified version of the Samson C-Rover:

In particular, it has a fishing cockpit similar to the C-Reaper combined with a substantial bulwark forward that extends above the deck:

The builder had plans of fishing the boat - hence the cockpit, a huge insulated fish hold, and even an ice flaking machine. And the trolling valve that I use on occasion. The builder did many things right - 1100 gallons of fuel in 4 insulated fiberglass tanks, very skookum running gear, all Diamond Sea Glaze windows - and many things that are truly mediocre - wiring and plumbing in particular. He died soon after launching the boat, which was then bought as a liveaboard by a lady psychologist who removed all of the electronics, dinghy davit, etc. and installed house-sized kitchen appliances. Full-size fridge, electric range, trash compactor, disposal - even separate water heaters for the head and galley. I bought it from her, and I still have the disposal - very handy for transforming 30 pounds of garbage into 30 pounds of smaller garbage.

As I think everyone's aware, ferro-cement didn't survive in North America, though it's still thriving on a small scale in NZ and Australia. But back in the 70s it held great promise - here are a couple of designs by someone I think everyone's heard of: