Pack Mule

TF Site Team

- Joined

- Jan 24, 2013

- Messages

- 3,749

- Location

- USA

- Vessel Name

- Slo-Poke

- Vessel Make

- Jorgensen custom 44

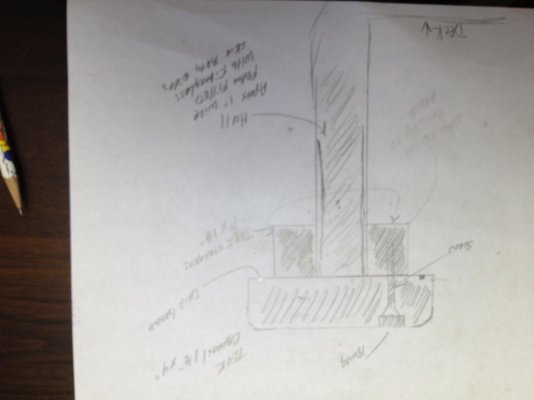

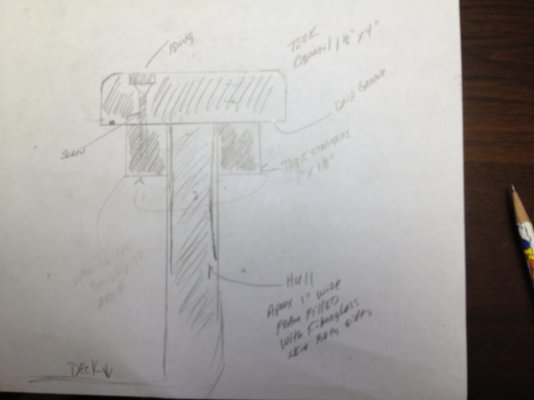

This is what I'm thinking about for new cap rail . What is the best way to attac the teak stringers to the hull ? One sugesstion was to thru bolt them thru the hull with 5200 as the adhesive countersink and bung the holes. I plan on using 4200 or something similar under the cap rail . Does this look like a decent cap rail idea? Getting the stringers attached to the hull is my most concern right now . Mine is similar but only has a stringer on the outside . I'm not sure what is under the cap rail now to screw to . Sorry I have tried 3 times to rotate the drawing.