PennBruce

Senior Member

- Joined

- Apr 12, 2021

- Messages

- 208

- Vessel Name

- Last Hurrah

- Vessel Make

- Ta Chiao/CT35 Sun Deck

I was drilling a hole in a locker and damaged one of the hydraulic steering tubes.

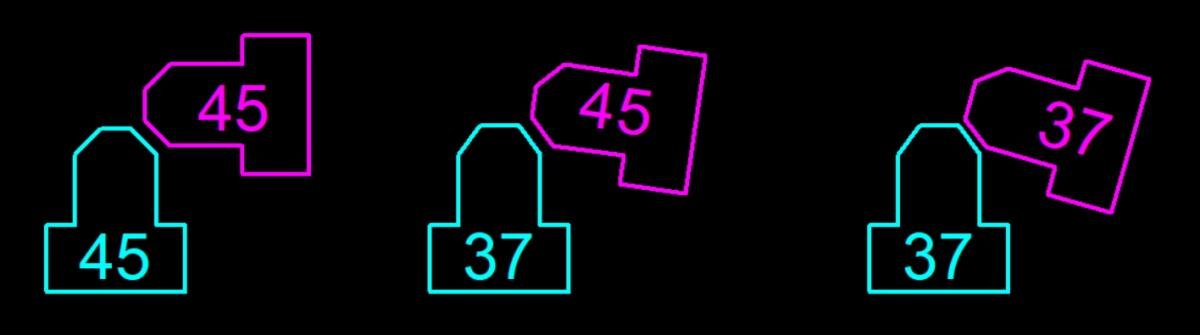

The view is from the engine compartment looking up at the floor of the locker. As you can see the drill bit did a nice job on the tubing.

Searching the forum indicates that the fix is to piece in a length of tubing with compression fittings. The tubing is 3/8 inch.

My only experience with compression fittings is fitting bathroom sinks.

Suggestions and advice will be appreciated.

Bruce

The view is from the engine compartment looking up at the floor of the locker. As you can see the drill bit did a nice job on the tubing.

Searching the forum indicates that the fix is to piece in a length of tubing with compression fittings. The tubing is 3/8 inch.

My only experience with compression fittings is fitting bathroom sinks.

Suggestions and advice will be appreciated.

Bruce

Sometimes it THIS guy..lol.

Sometimes it THIS guy..lol.