Scottwb96

Senior Member

I was planning on switching out my current block heaters (Kat freeze plug style, screws into the block). Not a fan of their short life cycles and when they go out, the block basically needs to be drained and refilled to put the new ones in (big mess)...

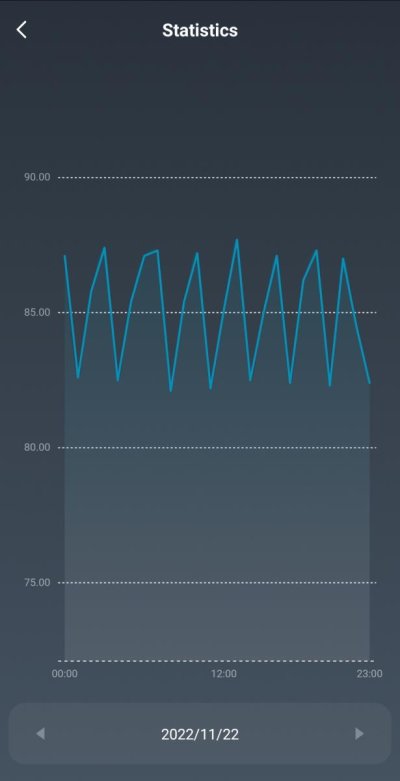

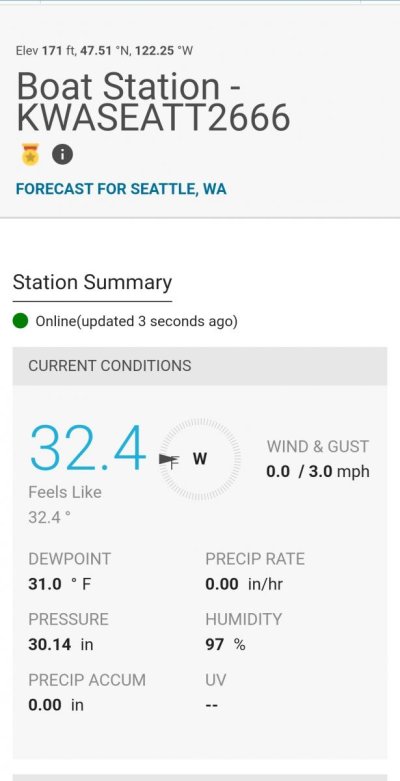

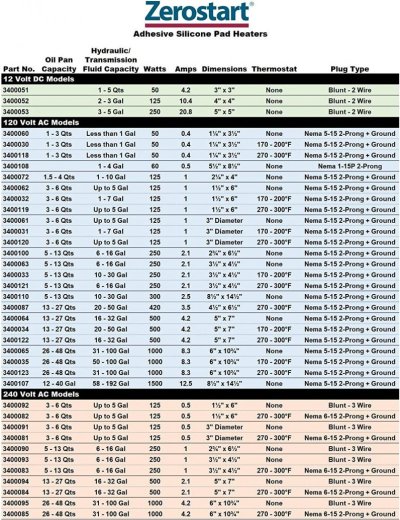

That being said, I was thinking the HotStart TPS style might be a better option. I could add shut-off valves to allow for easy replacement when the time comes. I was also looking at the different wattage options. I am in the PNW (Washington) so temps don't get too ridiculous here... So, I was hoping to use a MUCH smaller wattage option then the recommended chart (1,800w). Currently I have a single 750 watt option on/IN each engine. I have them hooked up to temp switches that go on/off to regulate the temps to keep them right at about the mid-80's. If I just let them run, the temps can easily get up to about ~100° (or higher). Those single units keep the engines right about 82°-87° which in turn, also keeps the ambient temp in the boat sitting at about 55°-60° (which was a nice added benefit).

So, I was hoping to use a MUCH smaller wattage option then the recommended chart (1,800w). Currently I have a single 750 watt option on/IN each engine. I have them hooked up to temp switches that go on/off to regulate the temps to keep them right at about the mid-80's. If I just let them run, the temps can easily get up to about ~100° (or higher). Those single units keep the engines right about 82°-87° which in turn, also keeps the ambient temp in the boat sitting at about 55°-60° (which was a nice added benefit).

Would dropping the HotStart down to the 500w model/option still work in this scenario to keep everything at a decent block temp?

When I do the switchover, I was also wanting to add a hydronic heater to the mix. I am guess-timating about a 4'-5' rise from the top of the HotStart to the hydronic inlet. Where I am starting to second guess things is the coolant flow and how that might not work properly. The Hydronic heater would be above the coolant recovery tank, so wouldn't this cause the in/out flow to the tank to be off, due to the differing elevations? Or am I completely off since this is a pressure push/pull system???

Below is a ROUGH idea of what I was going to do...

Appreciate any thoughts or insight!!!

That being said, I was thinking the HotStart TPS style might be a better option. I could add shut-off valves to allow for easy replacement when the time comes. I was also looking at the different wattage options. I am in the PNW (Washington) so temps don't get too ridiculous here...

Would dropping the HotStart down to the 500w model/option still work in this scenario to keep everything at a decent block temp?

When I do the switchover, I was also wanting to add a hydronic heater to the mix. I am guess-timating about a 4'-5' rise from the top of the HotStart to the hydronic inlet. Where I am starting to second guess things is the coolant flow and how that might not work properly. The Hydronic heater would be above the coolant recovery tank, so wouldn't this cause the in/out flow to the tank to be off, due to the differing elevations? Or am I completely off since this is a pressure push/pull system???

Below is a ROUGH idea of what I was going to do...

Appreciate any thoughts or insight!!!