Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,110

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

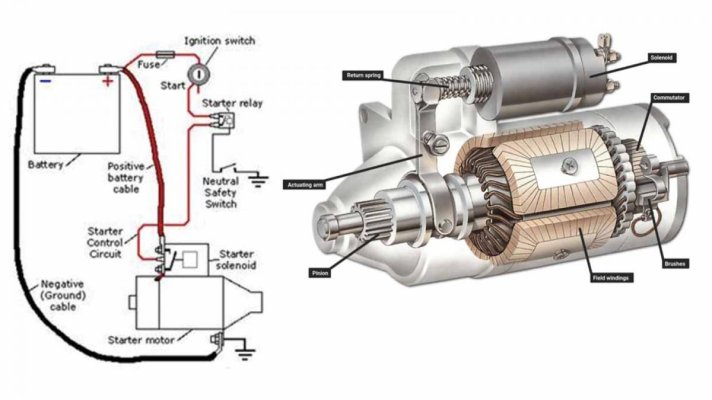

Went to start up yesterday and nothing. After lifting the engine hatch, I could tell it wasn't quite nothing. The starter would spin. I tried the shade tree mechanic "fix" of tapping the solenoid with a hammer. That seemed to make it "click" louder when the start button was pushed, but still didn't engage. I cleaned all the electrical contacts on the starter, the solenoid, and the relay. Checked for voltage (but not voltage drop) at the starter, etc. Since I could hear the starter spinning, I didn't think that voltage was the issue. Battery monitor showed 12.4V dropping into the high 11's when starter was spinning.

I would love to not have to take starter and solenoid out and still have a fix that left me confident that the issue would not arise in the future. Anybody have a "fix-in-place" solution?

From reading old posts here, one solution was to purchase a new starter/solenoid ($325) and simply replace, having the old one rebuilt as a spare. Although my problem seems to be just the solenoid, some claimed that replacing just the solenoid wasn't much of a cost/time savings over replacing the whole thing. Of course because it is a boat, a Ford Lehman starter/solenoid was $325 where an identical looking Ford was $250 and cross referencing to a generic identical looking starter was $185 at the local auto parts. Anybody replaced theirs with a generic starter?

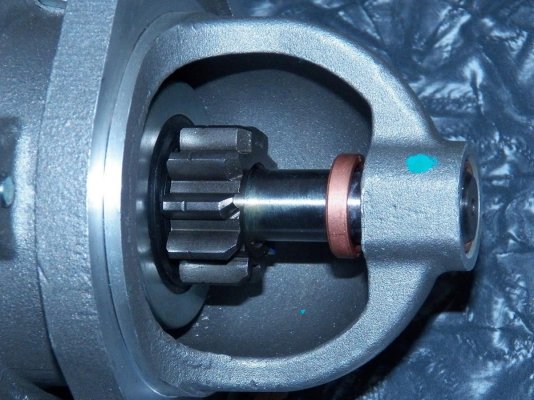

The pictures I found of the "official" Ford Lehman starter don't look quite right. Here is a picture of one that looks to me like it would fit on the starboard side of the engine (with the solenoid on top). Maybe it's just a generic picture? The gear housing also doesn't look like mine. And it is a Lucas part. Lucas may have been the original part supplier, but given my experience with Lucas I would just as soon have a Chinese Brand X.

All advice, experience, part numbers, warnings, etc. appreciated.

I would love to not have to take starter and solenoid out and still have a fix that left me confident that the issue would not arise in the future. Anybody have a "fix-in-place" solution?

From reading old posts here, one solution was to purchase a new starter/solenoid ($325) and simply replace, having the old one rebuilt as a spare. Although my problem seems to be just the solenoid, some claimed that replacing just the solenoid wasn't much of a cost/time savings over replacing the whole thing. Of course because it is a boat, a Ford Lehman starter/solenoid was $325 where an identical looking Ford was $250 and cross referencing to a generic identical looking starter was $185 at the local auto parts. Anybody replaced theirs with a generic starter?

The pictures I found of the "official" Ford Lehman starter don't look quite right. Here is a picture of one that looks to me like it would fit on the starboard side of the engine (with the solenoid on top). Maybe it's just a generic picture? The gear housing also doesn't look like mine. And it is a Lucas part. Lucas may have been the original part supplier, but given my experience with Lucas I would just as soon have a Chinese Brand X.

All advice, experience, part numbers, warnings, etc. appreciated.