My teak was bedded in a rubber compound and screwed down. The screws mostly had to be turned out with vice grips after prying off the teak with hammer and those 2 inch wide flat pry bars, sometimes resorting to hammer and chisel, when unable to catch an edge of the teak otherwise. Cleaning off the rubber bedding was mostly angle grinder with the metal sanding flap discs.

Removal is best done from scaffolding of some sort so standing leaning in, but also on deck with a stool and padding to lean your chest on so to work with both hands.

Crunch time is a careful survey of the deck when clean to fiberglass with a tapping hammer. A steel hammer is not tuned for the job. With a little practice you can map soft core, sketching it out with marker as you go.

Cut out sections of skin where needed leaving an inch or inch and a half intact next to the walls that will have to be dug out from the side, painful, but that lip is needed for strength in the rebuild. Don't bother with long lifts of skin, keep them to 18 inches or so with cross members left joining side to side and being 2 inches wide, and relatively easy to clean under and wet out when you get to it. Clean up the removed skins of all adhesives and sand them to make ready of top and bottom fiber glassing. I prepped my skins with holes to allow air to escape when put back in place. I.e. resin will ooze up from the holes if all is well.

I used balsa core and glass layers/resin above and below to fill the void, leaving room for one final glass layer/resin to accept the skin. The balsa sheets have the advantage of being really easy to size to the void using only a blade. And, they wet out thoroughly so are not going to rot in any relevant lifetime. Anyway, the water is not going to get to the core with a sealed top. I find the result strong and firm so options that might theoretically be better engineering solutions may be overkill, outside the side decks that might be a real consideration.

Did I mention all the sanding this all entails.

I am finishing with a layer of heavy fiberglass over the whole deck before moving on to the coatings for finish and non-slip.

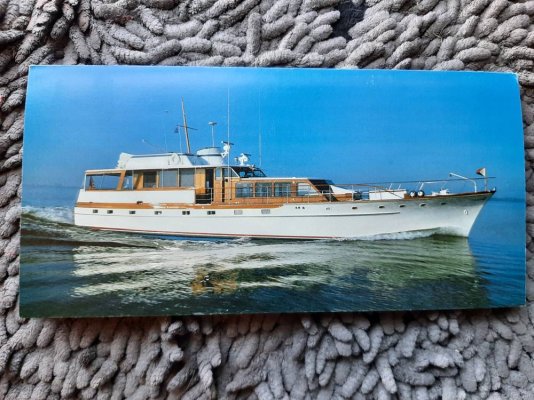

My checkbook mysteriously flew open.

My checkbook mysteriously flew open.