Does it shut down immediately after a cold start, or only after it has warmed up?

There are three safety shutdown switches, all wired in parallel to ground. If any one of the safety switches closes, it grounds the gray wire and shuts down the generator. When the glow plug switch is held on, the safeties are bypassed and ignored, but as soon as you release the switch, they become enabled and will shut down the generator if active. You ca see how this works in the wiring diagram in the manual, which is available from NL online.

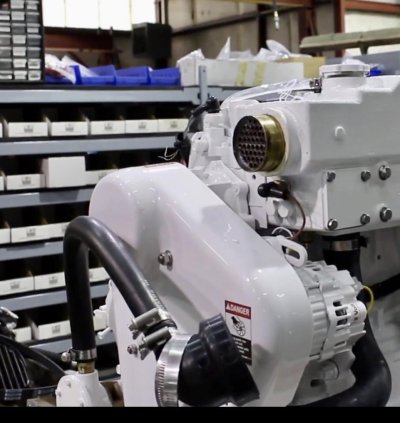

To figure out which switch is shutting down the generator, you need to disconnect them one at a time and see if the generator keeps running. The switches are:

Start with the exhaust temp switch. You will have had to move it from the old exhaust elbow to the new elbow, and it might have been damaged in the process. Disconnect one of the white wires and see if the generator will now keep running. If it does, you need to make sure that your exhaust isn't actually overheating, especially since you just trashed an impeller and may not have a fully fixed raw water cooling system. Be careful checking, but when running, the exhaust hose coming off the elbow should be cool to the touch, or at most warm. You should also have good water flow out of the exhaust. If the hose is hot, stop the generator immediately. You have inadequate raw water flow and need to fix it. The safety switch is doing it's job and saving you.

If that isn't the problem, then try the other two switches which are coolant temp and oil pressure. Don't confuse the safety switches with the coolant temp sensor and oil pressure sensor. The safety switches both have a gray wire on them. If either is stopping the engine then you need to figure out if you have a real overheat or low oil pressure problem. But since you have been recently working on the raw water cooling system, including the safety switch, the overwhelming probability is that it's the problem, not the oil or coolant switches.