As noted below in this thread moisture meters are not the most accurate. Read this

Moisture Meter Mythology and it's a good idea to poke around his entire web site. A wealth of information.

The Californians of that vintage, I have an '83 42 LRC, have solid hand laid hulls. When I had a new through hull installed the plug cut out of the bottom was about 1 1/4" thick. And when a new hydronic furnace exhaust port was cut in the side that was over 3/4" thick.

The decks, cabin sides and cabin tops are glass over ply. Typical of boats of that era.

Regarding what your surveyor calls the deck stringers it is important to know which stringers he's talking about, where they are. That will determine the difficulty in repair / replacement. If in a difficult to access area or where a lot of wiring etc has to be moved it will be expensive. But technically I don't think replacing stringers in an older Californian is challenging. If only the stringers are compromised. The construction is simple and straight forward.

Regarding 30% moisture content. Yes, that's a lot. Very wet wood. That does not mean the wood has rotted yet. Yet. It will if not dried out. Go back to the boat with your hammer and tap, tap, tap. You won't gain the expertise to really evaluate in a few hours. But you will be able to find serious rot. Start in areas you know are good then move to the area in question and note the difference. Maybe start in the middle of the engine room an area almost certainly to be dry and sound. Though your OP says

stringers on the engine compartment etc

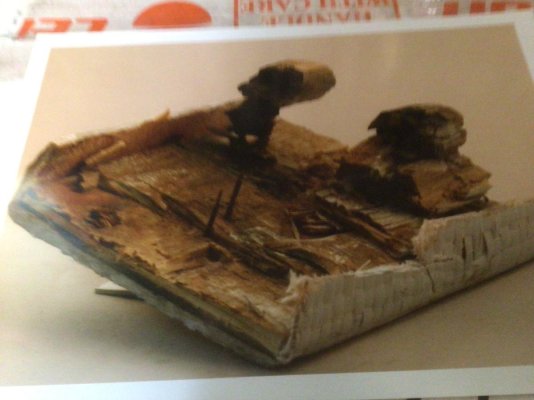

If the stringers are soft then question the plywood above. Regarding the surveyor's suggestion to bore holes, as has been said that isn't going to happen until you own the boat. Take a sharp pocket knife with you. If / when you find a soft spot with the hammer try poking it with the knife. If the knife penetrates the wood it's rotten, very rotten.

To give you a sense of how extensive it can be. A buddy with a similar vintage CHB found soft stingers under the cockpit. Before he was done the entire cockpit was torn out. I had a "little" wet spot under the port forward port light. That little spot got quite big when all the rot was removed.

I'm no surveyor, I do in the dim dark past have some boat building experience. So take this next with a grain of salt, heck an entire salt shaker....

I'm very curious about wet stringers in the engine room. The water got in there somehow. The cabin covers the engine room. I'd want to spend the necessary time trying to figure that out, find out what else is wet, what else might be rotten. If the 34 is built like the 42 then the hull sides are solid to the cap rail. Under cap rail it is glassed heavily. The structure from the cap rail down to the deck is heavy glass. None of that provides an easy path for water to enter. The deck and house as I said above are glass over ply unless you find cracks or failures there then also an unlikely place for water to enter. That leads me to guess the water came from the cabin sides, probably the windows. Boat windows of that era are notoriously leaky. And again, if the 34 was built like the 42 it will be hard to find. I learned when installing a new refer that as stated above the cabin sides are glass over ply. Then inside that, the back of the cabinets etc is another sheet of 1/2" ply which is the back of the cabinets held off the cabin side structure by blocks or shims or something. So you can't see, tap and check for moisture the ply of the cabin sides. I'd start with tapping and moisture meter around the windows.

In closing if you are interested in a 40 yr old boat because it's cheaper than newer. Very likely it won't be by the time you're done. Anything built in 82 is likely to have problems. Do your best to find them and make a careful decision. There will always be problems you or the surveyor didn't find.

I am looking at purchasing a 34 ft Californian LRC. Located on the Mississippi River. I hired a boat surveyor to inspect the vessel. His hull moisture readings look good. However as he inspected the deck and stringers on the engine compartment etc, he was getting readings of 30%. At that point he stopped and conferred with me on how I wanted to proceed. He mentioned boring small inspection holes to confirm if the wood is rotten at all.

Anyone have experience on how the ascertain the condition of the stringers etc? Any advice/experience is welcome. This is my first trawler purchase and I’m new on here, so thank you in advance!

Curious.

You say painted no fiberglass…

What can I expect as to moisture?

I see this boat as a fiberglass hull.