scurvydog_pnw

Veteran Member

- Joined

- Dec 27, 2020

- Messages

- 63

Hello peeps,

Happy memorial day. Looking for advice on a JD 4045 engine that started having problems over the winter. Dual engine setup on our boat with engines at 430 hours.

When returning from the yard this April our Starboard engine died while coming into the dock and would not restart.Engine would crank but, not fire. No prior history of issues on this engine.

Had a JD mechanic come in and troubleshoot for us. Assuming a fuel supply issue we identified that the fuel pump outlet nut was not as tight as it should have been and we believed it allowed air to enter into the lines to the injectors. Tightened the nut and cracked the injector fuel lines and bleed the lines and then engine started. All around smiles.

Last week we attempted to head out for cruising and the Starboard engine was having issues starting. Cranking but, not firing. On fourth attempt engine started. I ran it for a few minutes shutdown for 2 minutes and then fired back up on first try. Unfortunately engine died 11 minutes. Engine would crank but, not fire.

So some data points.

Since the Starboard engine ran dry I cracked the nut on the fuel pump egress and cranked the engine until it purged diesel. Then I did the same on the injectors. Diesel coming out of the fuel lines to the injectors. Still not firing.

So it should be getting fuel and it cranks so not sure what went wrong.

On the one time error code the service manual says check sensor and wiring. Not sure which sensor they are talking about as the primary throttle linkage on the engine is in the correct mechanical spot to for neutral.

Thoughts from the community as it may be weeks before I can have an technician come out for further testing.

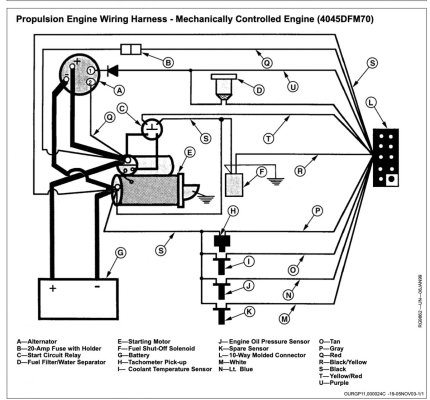

Attached is the wiring diagram from my engine manual.

Happy memorial day. Looking for advice on a JD 4045 engine that started having problems over the winter. Dual engine setup on our boat with engines at 430 hours.

When returning from the yard this April our Starboard engine died while coming into the dock and would not restart.Engine would crank but, not fire. No prior history of issues on this engine.

Had a JD mechanic come in and troubleshoot for us. Assuming a fuel supply issue we identified that the fuel pump outlet nut was not as tight as it should have been and we believed it allowed air to enter into the lines to the injectors. Tightened the nut and cracked the injector fuel lines and bleed the lines and then engine started. All around smiles.

Last week we attempted to head out for cruising and the Starboard engine was having issues starting. Cranking but, not firing. On fourth attempt engine started. I ran it for a few minutes shutdown for 2 minutes and then fired back up on first try. Unfortunately engine died 11 minutes. Engine would crank but, not fire.

So some data points.

- Both engines start from the same battery bank.

- Both engines pull from the same fuel manifold.

- Port engine fires up just fine.

- All fuel valves confirmed open.

- Verified fuel in tank through site gauge

- Fuel level lower then expected in Racor when I removed the filter. 2.25" from housing top with filter removed. Used to see fuel all the way to the top of the housing when filter installed.

- Filters clean and spotless. No sign of water or bacteria contamination

- No errors thrown on the engine computer display

- On first day of failure the engine computer through an error code which was secondary analog throttle signal out of range low. Restarted computer and error code had not reappear.

Since the Starboard engine ran dry I cracked the nut on the fuel pump egress and cranked the engine until it purged diesel. Then I did the same on the injectors. Diesel coming out of the fuel lines to the injectors. Still not firing.

So it should be getting fuel and it cranks so not sure what went wrong.

On the one time error code the service manual says check sensor and wiring. Not sure which sensor they are talking about as the primary throttle linkage on the engine is in the correct mechanical spot to for neutral.

Thoughts from the community as it may be weeks before I can have an technician come out for further testing.

Attached is the wiring diagram from my engine manual.