albinalaska

Veteran Member

- Joined

- Jun 6, 2020

- Messages

- 94

- Location

- USA

- Vessel Name

- Sea Gypsy

- Vessel Make

- 1979 Albin Trawler 36'

Good day all!

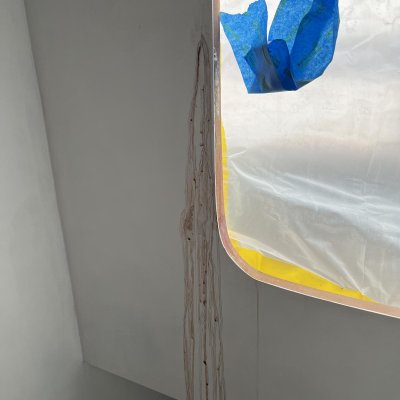

Been restoring our trawler and have been away for some time but returned to the vessel today to find some rather confusing issues with one of our newly sealed windows.

There is brown liquid residue that’s weeping out of a missed seam around the window. Obviously that means the windows aren’t sealed as though and I need to dig it out but I haven’t seen this except for on houses.

Anyone have any insight, experience or advice? There is a chain plate for a stanchion for the mast directly above the frame but there are weeping issues along the top edging of the frame as well.

@mv_seagypsy on IG for those who want more context.

Been restoring our trawler and have been away for some time but returned to the vessel today to find some rather confusing issues with one of our newly sealed windows.

There is brown liquid residue that’s weeping out of a missed seam around the window. Obviously that means the windows aren’t sealed as though and I need to dig it out but I haven’t seen this except for on houses.

Anyone have any insight, experience or advice? There is a chain plate for a stanchion for the mast directly above the frame but there are weeping issues along the top edging of the frame as well.

@mv_seagypsy on IG for those who want more context.