You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crossover fuel line

- Thread starter BrianG

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

GoneDiving

Senior Member

Where your unfinished lines from the shutoff valves meet at the fuel pump will provide a path for fuel to flow from Tank 1 to Tank 2. If there are no check valves inline then levels can balance through there

Note you may also have return lines in the mix as well. These may be what you see as the vent lines from the engine to the top of the tanks.

Note you may also have return lines in the mix as well. These may be what you see as the vent lines from the engine to the top of the tanks.

CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,551

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

Crossover line would be at the toward the bottom of tanks.

BrianG

Senior Member

That's where I expected to find it. Wasn't there.Crossover line would be at the toward the bottom of tanks.

BrianG

Senior Member

Those vent lines for sure go vertical and exhaust at the roofline. I'll inspect that fuel pump tomorrow. ThanksWhere your unfinished lines from the shutoff valves meet at the fuel pump will provide a path for fuel to flow from Tank 1 to Tank 2. If there are no check valves inline then levels can balance through there

Note you may also have return lines in the mix as well. These may be what you see as the vent lines from the engine to the top of the tanks.

CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,551

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

I had 1 inch crossover line, it was actually a blue hydraulic hose, connected to the gate valves at the bottom of the tank.

What boat are you on?

What boat are you on?

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,867

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

If both lines that feed the engine, contain no check valves, then that loop becomes a siphon. Fuel will naturally flow from the tank with the higher level to the lower level.

Also, when the engine is running, the lift pump on the engine will naturally draw from the tank with the higher level as it requires less vacuum to lift the fuel to the pump. If the engine is below the fuel level in the tanks, the tank with the higher fuel level will exert a greater pressure and be the one feeding the engine, until the tanks are equal.

You're very lucky if the boat sits level when the fuel levels are equal. For many boats with tanks empty the boat lists to port or starboard. Fuel in tanks with a list, tend to move to the lower tank,further increasing the list.

Ted

Also, when the engine is running, the lift pump on the engine will naturally draw from the tank with the higher level as it requires less vacuum to lift the fuel to the pump. If the engine is below the fuel level in the tanks, the tank with the higher fuel level will exert a greater pressure and be the one feeding the engine, until the tanks are equal.

You're very lucky if the boat sits level when the fuel levels are equal. For many boats with tanks empty the boat lists to port or starboard. Fuel in tanks with a list, tend to move to the lower tank,further increasing the list.

Ted

Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,110

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

Fuel in tanks with a list, tend to move to the lower tank, further increasing the list.

That may answer a question I've had about the prior owner's label on the dual tank manifold. An vintage Dymo label says "one open valve," i.e. draw from one tank at a time. I've ignored it and run from both a few times and I have left both open a few times at the dock to balance the tanks. But I guess that has only worked because the boat was fairly level.

I could see where one tank at a time might arguably provide kind of an emergency reserve if I didn't check fuel levels every day. Running out of fuel in one tank is only slightly less problematic than running completely out of fuel. And the real problem would be with my monitoring.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,867

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

That may answer a question I've had about the prior owner's label on the dual tank manifold. An vintage Dymo label says "one open valve," i.e. draw from one tank at a time. I've ignored it and run from both a few times and I have left both open a few times at the dock to balance the tanks. But I guess that has only worked because the boat was fairly level.

I could see where one tank at a time might arguably provide kind of an emergency reserve if I didn't check fuel levels every day. Running out of fuel in one tank is only slightly less problematic than running completely out of fuel. And the real problem would be with my monitoring.

Don't forget the return line! If you choose to run off of only one tank, you need to make sure the return fuel from the engine is only going to that same tank. More than one boater has drawn from the port and returned to the starboard until the tank ran dry.

Ted

rslifkin

Guru

- Joined

- Aug 20, 2019

- Messages

- 7,584

- Location

- USA

- Vessel Name

- Hour Glass

- Vessel Make

- Chris Craft 381 Catalina

Don't forget the return line! If you choose to run off of only one tank, you need to make sure the return fuel from the engine is only going to that same tank. More than one boater has drawn from the port and returned to the starboard until the tank ran dry.

Ted

Or until the tank receiving the return flow became over-full and puked a bunch of fuel out the vent.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,280

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Or until the tank receiving the return flow became over-full and puked a bunch of fuel out the vent.

And this is way worse, potentially huge fines.

CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,551

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

My tanks had a crossover but only returned to the starboard tank.

Or until the tank receiving the return flow became over-full and puked a bunch of fuel out the vent.

It will happen. One of boating's universal rules, is that the returning fuel will overflow the tank not being used, long before the one is use is empty.

Or until the tank receiving the return flow became over-full and puked a bunch of fuel out the vent.

Been there. After topping-off both saddle tanks, I had only been underway for half an hour when for no particular reason I glanced over the starboard side and saw fuel pouring out of the vent fitting. Instantly I realized what was happening. The return lines went to the starboard tank only. Thinking to fill each tank more efficiently, I had closed the valve in the crossover line. Once finished fueling, I left it that way, a boneheaded mistake I'm unlikely to repeat.

Good decisions come with experience. Experience comes from poor decisions.

CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,551

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

Been there. After topping-off both saddle tanks, I had only been underway for half an hour when for no particular reason I glanced over the starboard side and saw fuel pouring out of the vent fitting. Instantly I realized what was happening. The return lines went to the starboard tank only. Thinking to fill each tank more efficiently, I had closed the valve in the crossover line. Once finished fueling, I left it that way, a boneheaded mistake I'm unlikely to repeat.

Good decisions come with experience. Experience comes from poor decisions.

Done that too, transferring fuel between tanks, only in our case a Coast Guard Cutter was following behind us about a mile.

Luckily we happened to be leaving the bay at the same time the halibut fleet was heading for a 24 hr opener.

Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,110

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

My return goes only to the starboard tank. The Lehman 120 is known for the tiny amount that is returned. Mine is a Lehman 80, which has a smaller injector pump, and probably returns even less.

One time I marked the starboard site tube with masking tape and cruised about 10 hours on the port tank. It was difficult to tell if the return raised the level in the starboard tank. Maybe an 1/8th of an inch (a little over a gallon). I would have to have the return tank really full and run for days on the other tank before it would be an issue. But . . . if it can go wrong. Note to self: best to start on the starboard tank after leaving the fuel dock.

One time I marked the starboard site tube with masking tape and cruised about 10 hours on the port tank. It was difficult to tell if the return raised the level in the starboard tank. Maybe an 1/8th of an inch (a little over a gallon). I would have to have the return tank really full and run for days on the other tank before it would be an issue. But . . . if it can go wrong. Note to self: best to start on the starboard tank after leaving the fuel dock.

BobMc

Senior Member

- Joined

- Feb 5, 2012

- Messages

- 112

- Vessel Name

- Sanderling

- Vessel Make

- DeFever 41

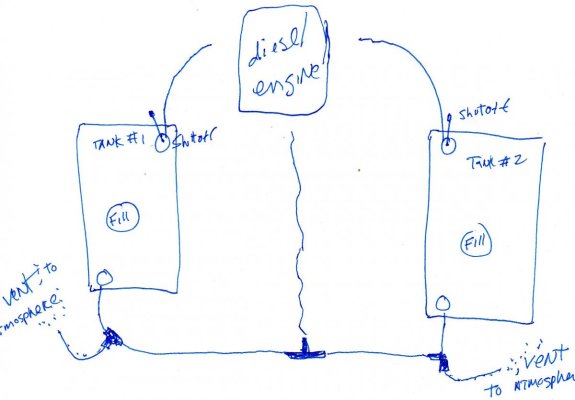

Single engine diesel. two fuel tanks. The fuel levels read the same in each tank so there must be a crossover line. But the only thing that looks like a crossover line vents the fuel tanks. I'm not seeing the big picture here. A little help? Kinda lost.

From your drawing you have the same setup we had on Sanderling. Just keep both valves at the tanks (or other shut-offs in the fuel lines) open and there won't be a problem. The fuel lines from each tank to the center draw acts as a crossover line, as others have explained.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,218

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

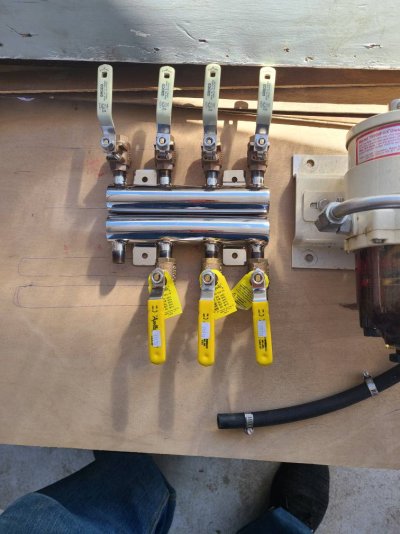

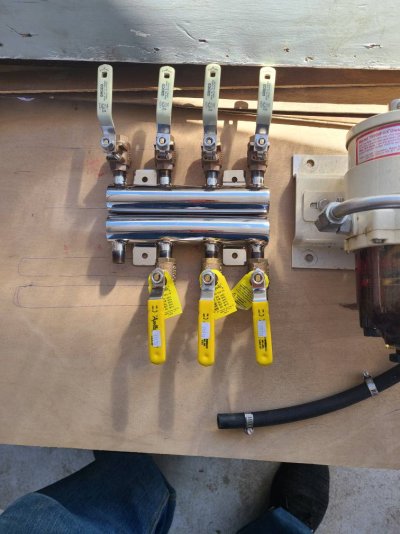

I am in the process of upgrading fuel tank plumbing. Originally I considered Groco fuel selector valves - one for supply, one for return. Ended up going with a manifold setup which to me is easier to manage (Pic shows only three valves on bottom manifold - one of the four valves I purchased was wrong size and I am waiting for replacement). Single engine with saddle tanks - fourth port on manifold is for polishing/transfer pump. Very simple system, but transfer or polishing should only be done at rest to avoid fuel contention with engine.

I did not plumb in a crossover but could allow gravity to balance tanks via the manifold when tanks are more than half full, or use the transfer pump.

Peter

I did not plumb in a crossover but could allow gravity to balance tanks via the manifold when tanks are more than half full, or use the transfer pump.

Peter

Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,110

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

I may have figured out why the PO had a message on the fuel manifold to only have one valve open at a time. My sight glasses are down stream of the tank shut off valve (which causes the issue). If the port tank is half full and I shut it off, but have both valves open at the manifold, I end up measuring the starboard tank (with both sight glasses). If the starboard tank is full and I then shut off the port manifold valve, the port tank sight glass would stay at that incorrect level (the of the starboard tank). It would read full when only half full. The tanks couldn't level out because both the port manifold and tank valves were closed. If I run the starboard tank empty and then open the valves to the port tank, it will then correct itself and, surprise, I'll find out that it was still holding the full sight glass when the tank is only half full.

POs solution was to only have one manifold valve (and the appropriate tank valve) open at a time in order to not get a crossover reading locked into a sight glass. That explains why I've seen the sight glass levels jump around a few inches when switching the fuel valves.

Confusing? I could replumb the sight glasses. Or I could be aware and follow the instructions on the manifold.

POs solution was to only have one manifold valve (and the appropriate tank valve) open at a time in order to not get a crossover reading locked into a sight glass. That explains why I've seen the sight glass levels jump around a few inches when switching the fuel valves.

Confusing? I could replumb the sight glasses. Or I could be aware and follow the instructions on the manifold.