Some questions and comments:

What is your current 24v 120a charger that you mention? Can it have additional alternators or generators fitted?

It's the 5000/120 amp victron multiplus we have

Power for that when required is a 7kVA genset head on a 21hp Kubota that was a hard runner when made.

But it doesn't produce full power as it's been wound back by previous owner (to noisy before) to 1500rpm so only getting around 4kva now

Would your dead alternators have survived if they had a simple temperature controller added? It would be fairly easy and cheap to add the main features of the external regulators: a temp controller, an output shut off regulator and a small LA battery for when output is terminated. The main feature that I see as difficult to replicate would be load throttling to prevent over heating but the temp controller and relay could achieve this via a crude form of PWM.

Maybe, don't know, not wanting to guinea pig another one together to try - not if I can get real power for similar coin

I'd agree with posts in the other threads that the cheap 3000/3600 rpm generator heads don't last long when run continuosly at high loads. We were killing these every few months on job sites when left to run aircons etc 24/7. Intermittent use for contractor tools is fine but continuous use killed them quickly.

.

I missed any mention on them not lasting in other threads

And running for several hours then a week off is not what I consider continuous use

Biggest days are probably 12 hours once or twice a year

Most are also designed for direct drive, relying on the drive shaft for bearings. Generally there is no allowance for the side loads present in a belt drive setup. Some form af bearing support would have to be added. Comparing like for like, a Chinesium 1500rpm 5 or 10kva head is only USD500 delivered. The down side is it's big and 120kg. Yes, Alibaba quality but I would be a lot more confident of these running 24/7 at 80% load than the high speed units. If required, name brands are also available.

Much of the comparison seems to be apples and oranges. I don't see much merit in comparing a full Balmar/Victron setup with a cheap generator head with diy control and wiring. Both have merits and issues but I see direct comparisons as misleading. Each to their own

.

Big and bulky is not an option

And that head was just an example

There are belt driven versions out there

The only reason I put balmar in the mix was it's there with pricing and what many seem to use - but not the way I want to go.

And Mecc Alte is an Italian build so I would not have thought it a "cheap" brand - more balmar is an expensive one (-;

In my mind the two budget options would be a $600 generator feeding direct to an inverter charger with that inverter providing the control logic. If the aim is providing charging for hours while underway, then I don't see rpm and frequency control as a difficult issue. Let's call it $1000 including diy install.

Exactly what I am trying to do.

With a name brand head

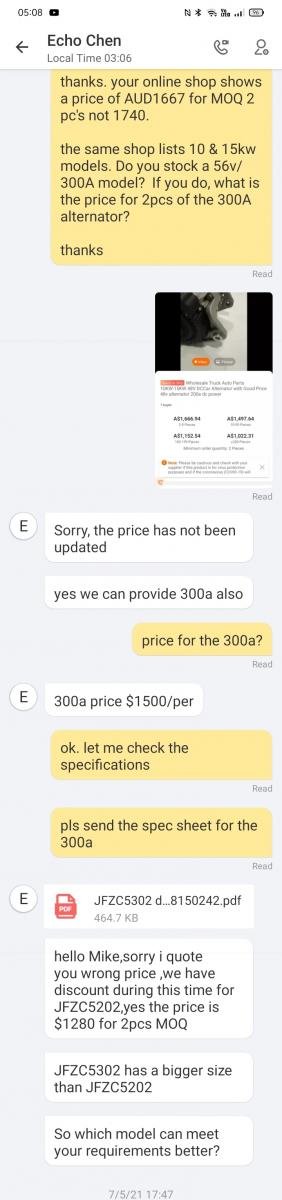

A large frame Chinese alternator is ~$1500 for up to 15kw. Add another $500 for temperature control, SLA bank and out put relay for a $2000 total.

Not if I can get a result for a grand like mentioned prior.

At the end of the day this is not a "need" it's a want

We have 2500w of solar - but recently, not much sun - first time in years - now the rains clearing out we are starting to see this big lifepo4 bank playing catch-up.

We have a Genset and charger that puts in 120amps/hour

A 3rd reasonable power generation source would be nice when underway and for under a $1000 I'd be keen but I don't need it for $3000