You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Removal/Replacement

- Thread starter appdiver

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

jwnall

Moderator Emeritus

When I had the engine (old Westerbeke) replaced in my Allied Mistress sailboat in 1994, they had to cut a hole in the cockpit to get the old one out and the new one in! No way that I am going to replace the two old Perkins in the current boat, but I will be curious as to what replies you get to this thread, so as to increase my knowledge.

John

John

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,196

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

On a 6 or 4 cylinder engine, removing stuff from the sides of the engine such as intake and exhaust systems, HXs, alternators etc normally allow the lifting devices such as El Sea mentions to work fine. Unbolting from the transmission may be required too. In most boats, the fridge is a bigger footprint than the engines. One of our 3 entry doors was sized to remove engines or fridge - this may be the case on your '79 MT, get out the tape.

There was a guy working on a boat at my marina (it had been pulled and blocked) who had a long arm mounted on a truck, sort of like a fork lift with only one fork.

He stuck it through the boat's cabin door, strapped the engine to it, lifted it, and pulled it out.

I'm sure there was more to it than that but I didn't stick around to watch.

He stuck it through the boat's cabin door, strapped the engine to it, lifted it, and pulled it out.

I'm sure there was more to it than that but I didn't stick around to watch.

For those of you without Marine Trader-type superstructures, the engine is approximately dead-center of the boat, several feet and 90 degrees from the nearest door out. Short of side window removal or a hole in the roof, anyone have direct experience removing the engine from this stye boat? Thanks!

Phil Fill

Guru

- Joined

- Oct 11, 2007

- Messages

- 2,919

- Location

- US

- Vessel Name

- Eagle

- Vessel Make

- Roughwater 58 pilot house

In the process of pulling Ford Lehman 120 from my '79 Marine Trader...what are the most viable logistics of getting it out of the cabin? Thanks for any suggestions!

So can the old engine be rebuilt in frame/where it sits? If so why do you want to repower especially on an old boat?

As mentioned I would stip the olde engine as much as possible to make it light as possible which include internal parts so only the block has to be removed. Once stripped an engine block is not that big and/or heavy that several bubbs can move. The Eagle has a hatch in the middle of the salon floor, so the block would be slip back as far as bossible and lifted out. I would not cut a hole in the hull as then the fuel tanks have to be cut out also.

If you have to replace, I would replace with an engine tht can be rebuild in frame/place. Our DD 671 can be rebuld in frame/place.

jwnall

Moderator Emeritus

There was a guy working on a boat at my marina (it had been pulled and blocked) who had a long arm mounted on a truck, sort of like a fork lift with only one fork.

He stuck it through the boat's cabin door, strapped the engine to it, lifted it, and pulled it out.

I'm sure there was more to it than that but I didn't stick around to watch.

I guess that is kind of how I thought it could be done -- some sort of mechanical arm sticking in the door and providing the muscle power. After all the attachments have been removed, of course, as has already been stated. And I suppose they change the really big house batteries in the same fashion. Although personally when my house battery needs to be replaced I am going to use multiple golf cart batteries. That is what I had on the sailboat (eight of them) and it worked very well, and they were easy enough to manhandle even for an old geezer like me.

John

magicbus

Senior Member

- Joined

- Nov 14, 2010

- Messages

- 460

I've seen the long boom are on a forklift here at a local marina. I have a "soft plug" in my ceiling. To pull mine the kitchen cabinets come out, the ceiling trim is removed and the floor of the flying bridge lifts out of the soft gasket plug so a crane can reach the main. I can't imagine what that would cost but at least it was built to allow it to happen.

Dave

Dave

CPseudonym

Moderator Emeritus

Once the block is lifted to the floor, plywood and a furniture dolly would make short work of rolling the engine to the doorway where the forklift can remove it through.

Thanks for the many helpful suggestions! I just can't be the only MT-style owner that's ever had to pull out an engine. Guess that's why the smart money back then was on the reliability and longevity of the Ford Lehman...they NEVER wanted to have to pull that baby out!

The engine gets stripped down to the basics, and usually a boom on a lift, could be a forklift, is used in conjunction with a manual or power winch to lift out the engine block and back it out of the cabin. I would be surprised if the boat is not designed to facilitate the removal of the engine in some manner without having to cut holes in the top, sides or bottom. Never heard of having the roof come off though.

Each boatyard could handle it differently.

Each boatyard could handle it differently.

skipperdude

Guru

Strip off all the bolt ons.

A front end loader with a boom or as suggested a fork lift. If the block will measure out the door she go's.

SD

A front end loader with a boom or as suggested a fork lift. If the block will measure out the door she go's.

SD

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

In the process of pulling Ford Lehman 120 from my '79 Marine Trader...what are the most viable logistics of getting it out of the cabin? Thanks for any suggestions!

Forklift crane boom and through the pilothouse door. At least that's how I did mine (on a Nordic Tug).

Don't know how an MT compares to a GB in cabin configuration, but on GBs the FL120 is stripped to the core. The whole main cabin sole of most GBs is comprised of easily removed sections. While the core can be maneuvered through the main cabin door on some models the most common process is to remove the large forward side window just aft of the main cabin door. The arm of a yard crane, or a fork extension on a forklift, is extended into the cabin through the window opening and the engine core is lifted out, turned, and removed through the window. The new engine goes in the same way.

mrbrzmc2

Member

Replaced both Perkins 6 354's in my Hershine all through a 24" door. Stripped off manicoolers, starters and alternators and winched them up to 4x6's then hoisted them out with a c frame on a boom truck. Just make sure the operator of the boom knows what they are doing. Also make sure you shore up the floor before setting a half ton of engine on it. Good luck brah.

motion30

Guru

- Joined

- Jan 14, 2010

- Messages

- 1,181

If it were me I would give those the fuel tanks a really good look while the motor is out

jwnall

Moderator Emeritus

RickB wrote:

" . . . the people who do this sort of thing for a living are quite good at it and have frames and the rigging to do it safely. It is amazing what they can do."

I think that is probably the bottom line. They have seen similar situations, no doubt, and know how to handle it. Expensive for us, to be sure, but I do not mind paying an experienced boat repair person for his experience. (And lest I get flamed, I would gladly say "his or her," but so far I have not seen a grizzled old marine handyperson of the female persuasion).

John

" . . . the people who do this sort of thing for a living are quite good at it and have frames and the rigging to do it safely. It is amazing what they can do."

I think that is probably the bottom line. They have seen similar situations, no doubt, and know how to handle it. Expensive for us, to be sure, but I do not mind paying an experienced boat repair person for his experience. (And lest I get flamed, I would gladly say "his or her," but so far I have not seen a grizzled old marine handyperson of the female persuasion).

John

Forkliftt

Guru

- Joined

- Oct 6, 2007

- Messages

- 2,450

- Location

- USA

- Vessel Name

- KnotDoneYet

- Vessel Make

- 1983 42' Present Sundeck

Looks like once you get that big V8 block out, a trolley of some sort and 4-5 "able bodies" would necessary!the people who do this sort of thing for a living are quite good at it and have frames and the rigging to do it safely. It is amazing what they can do.

Forkliftt

Guru

- Joined

- Oct 6, 2007

- Messages

- 2,450

- Location

- USA

- Vessel Name

- KnotDoneYet

- Vessel Make

- 1983 42' Present Sundeck

I would be nervous reaching a jib crane on a forklift inside a door on a trawler to lift an engine block. One inch of tilting back at the forklift would possible equal a foot and a half at the end of the boom. I like the trolley type approach in Ricks pictures. I also wondered if a monorail set up would work to get the engine outside the house.

the people who do this sort of thing for a living are quite good at it and have frames and the rigging to do it safely. It is amazing what they can do.

It seems the professionals also know how to do proper vessel protect. There must be 20 rolls of blue tape and at least a tree's worth of cardboard and plywood there plus some carpet in the pictures.

Last edited:

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

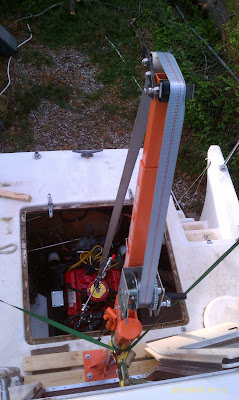

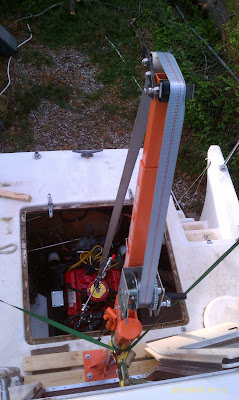

The folks who do this work know all the tricks and pitfalls. They don't want to pay for damage that can be avoided and know how to prevent it. That particular job was a big one so the frame was specially constructed to fit the engine and the boat but most of the time for smaller engines an aluminum frame monorail type lift is used. A beam trolley carries the load and the frames are leapfrogged until the engine is out of the boat to a place it can be lifted.

The photos show the old engine going out in pieces but the rebuilt engine was more or less in one piece except for the oil pan. There was not a great deal of room to spare going out and even less coming back in. The beauty of metal boats is that you can usually find a place to weld or bolt pads and eyes in the overhead and rig several chainfalls and come-a-longs to move stuff.

Here are a couple more of another removal job:

The photos show the old engine going out in pieces but the rebuilt engine was more or less in one piece except for the oil pan. There was not a great deal of room to spare going out and even less coming back in. The beauty of metal boats is that you can usually find a place to weld or bolt pads and eyes in the overhead and rig several chainfalls and come-a-longs to move stuff.

Here are a couple more of another removal job:

Attachments

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

I would be nervous reaching a jib crane on a forklift inside a door on a trawler to lift an engine block. One inch of tilting of back at the forklift would possible equal a foot and a half at the end of the boom. I like the trolley type approach in Ricks pictures. I also wondered if a monorail set up would work to get the engine outside the house.

You use the boom to rig off of. It remains stationary. It is a common practice in industry to use forklift booms to pull pumps and such if a monorail is not available.

Rigging is both a skill and an art. However, pulling an engine out of a boat is a pretty simple job as far as rigging goes.

Well I've done it on a Marine Trader 40 Europa. She had/has twin 120's that I needed to replace (I wont bore you with the details of why!) and basically the method has already been described.

Taking each engine in turn, lift the floor panels, erect an A-frame with block and tackle and lift engine to above floor level.

Replace the floor and lay under suspended engine either hardboard or ply on some old blankets.

Then lower engine and use wedges to keep upright and get a couple of strong guys to slide engine towards and near the rear door.

Get forklift (or telehandler in my case) with extension bar to get bar over engine and chain engine to bar.

Chosen lifting machine then lifts engine out slowly and carefully, no damage being caused!

Process repeated with next engine and installation is a reversal of extraction.

Whilst the engines were out I did indeed replace the starboard tank, I had to cut it out as it was too big to move in one piece and replaced with two tanks, mainly as it was easier to handle.

Apart from help moving the engine I pretty well did the rest of it on my own so it's no big deal just a lot of work that needs to be done carefully and safely!

'Hope this helps, I have some pics of tank being cut out and a couple of hazy pics (my son took as I was pushing engine out!) of engine being extracted if they're of interest.

Taking each engine in turn, lift the floor panels, erect an A-frame with block and tackle and lift engine to above floor level.

Replace the floor and lay under suspended engine either hardboard or ply on some old blankets.

Then lower engine and use wedges to keep upright and get a couple of strong guys to slide engine towards and near the rear door.

Get forklift (or telehandler in my case) with extension bar to get bar over engine and chain engine to bar.

Chosen lifting machine then lifts engine out slowly and carefully, no damage being caused!

Process repeated with next engine and installation is a reversal of extraction.

Whilst the engines were out I did indeed replace the starboard tank, I had to cut it out as it was too big to move in one piece and replaced with two tanks, mainly as it was easier to handle.

Apart from help moving the engine I pretty well did the rest of it on my own so it's no big deal just a lot of work that needs to be done carefully and safely!

'Hope this helps, I have some pics of tank being cut out and a couple of hazy pics (my son took as I was pushing engine out!) of engine being extracted if they're of interest.

jeffnick

Guru

Not a MT, and a relatively simple extraction, but might possibly inspire an idea.

Harbor Freight pickup bed crane <$150. There are horror stories about the wire cable winch...I converted it to strap.

Harbor Freight pickup bed crane <$150. There are horror stories about the wire cable winch...I converted it to strap.

awpptdt

Senior Member

- Joined

- Nov 7, 2010

- Messages

- 167

- Location

- U.S.A.

- Vessel Name

- Donnchaidh

- Vessel Make

- Marine Trader 40' sedan

I built an A frame out of 4"x6" tembers then used chain hoist to lift it out after I covered the floor with 3/4" osb. I also cut and placed 2/4"s between the stringers and the floor beams just as a precausion. I then mounted the engine on an engine stand and rolled it into the salon area where I disasembled it. As it turned out all it needed was new rings and gaskets. It was pulled because water had gotten in the rear cylinder, which cleaned up by honing it.

Similar threads

- Replies

- 4

- Views

- 629

- Replies

- 5

- Views

- 831