JD5652

Veteran Member

- Joined

- Feb 20, 2019

- Messages

- 90

- Location

- USA

- Vessel Name

- Miss Maggie

- Vessel Make

- 1976 Hatteras 58 LRC

This thread will document installation of a NIAID Stabilizer System in a 1976 Hatteras 58 Long Range Cruiser.

I chose the NIAID system for multiple reasons:

- History and Reputation of the System and Company

- Tried and True Technology

- Worldwide Support for Maintenance and Support

- Comparable Price of Other Systems

- USA Engineered and Manufactured System

The system consists of the following Major Components:

- Model 252 Electro-Hydraulic Actuator

- 6 Sq Ft Fins

- Oil reservoir with Integrated Heat Exchanger'

- Engine/Gear Driven Oil Pump

- 18" x 18" x 5" Mahogany Hull Reinforcing Blocks

- Center Lock Control Valve

- DC-DC Converter (10-36 VDC input - 24 VDC Output)

- Multi Sea Controller

https://www.naiad.com/wp-content/uploads/2020/07/Product-Flyer-162-302.pdf

https://pdf.nauticexpo.com/pdf/naiad-dynamics/multisea-ii-stabilizer-control-system/25361-15823.html

System install began on Tuesday 1/13/22 at Atlantic Yacht Basin. They will be performing the complete install.

This is the initial thread and I will post up progress and it goes along.

I chose the NIAID system for multiple reasons:

- History and Reputation of the System and Company

- Tried and True Technology

- Worldwide Support for Maintenance and Support

- Comparable Price of Other Systems

- USA Engineered and Manufactured System

The system consists of the following Major Components:

- Model 252 Electro-Hydraulic Actuator

- 6 Sq Ft Fins

- Oil reservoir with Integrated Heat Exchanger'

- Engine/Gear Driven Oil Pump

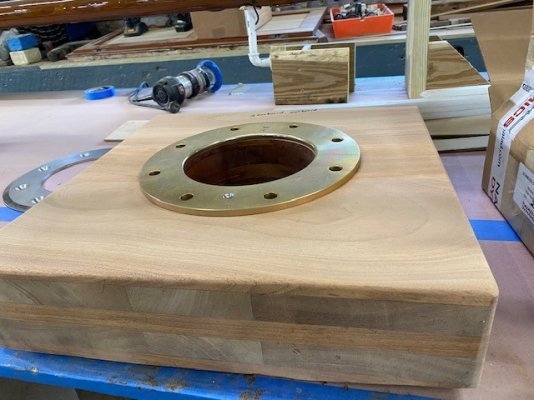

- 18" x 18" x 5" Mahogany Hull Reinforcing Blocks

- Center Lock Control Valve

- DC-DC Converter (10-36 VDC input - 24 VDC Output)

- Multi Sea Controller

https://www.naiad.com/wp-content/uploads/2020/07/Product-Flyer-162-302.pdf

https://pdf.nauticexpo.com/pdf/naiad-dynamics/multisea-ii-stabilizer-control-system/25361-15823.html

System install began on Tuesday 1/13/22 at Atlantic Yacht Basin. They will be performing the complete install.

This is the initial thread and I will post up progress and it goes along.

Attachments

-

Railway 01.jpg90.9 KB · Views: 62

Railway 01.jpg90.9 KB · Views: 62 -

Railway 02.jpg93.3 KB · Views: 59

Railway 02.jpg93.3 KB · Views: 59 -

Railway 03.jpg80.2 KB · Views: 49

Railway 03.jpg80.2 KB · Views: 49 -

Hull Hole Port Inside.jpg86.7 KB · Views: 50

Hull Hole Port Inside.jpg86.7 KB · Views: 50 -

Hull Hole Port.jpg100.9 KB · Views: 47

Hull Hole Port.jpg100.9 KB · Views: 47 -

Hull Hole Stbd.jpg100.3 KB · Views: 51

Hull Hole Stbd.jpg100.3 KB · Views: 51 -

Stabilizer Crate Parts Overall 05.jpg102.5 KB · Views: 48

Stabilizer Crate Parts Overall 05.jpg102.5 KB · Views: 48 -

Stabilizer Crate Parts Support Block 04.jpg113.4 KB · Views: 49

Stabilizer Crate Parts Support Block 04.jpg113.4 KB · Views: 49 -

Stabilizer Crate Parts 01.jpg110.4 KB · Views: 47

Stabilizer Crate Parts 01.jpg110.4 KB · Views: 47 -

Stabilizer Crate Parts Oil Reservoir 03.jpg102.1 KB · Views: 47

Stabilizer Crate Parts Oil Reservoir 03.jpg102.1 KB · Views: 47

Last edited: