HeadedToTexas

Guru

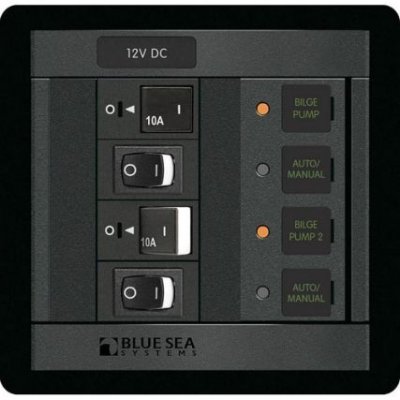

My first 12 VDC panel project has bubbled up to the top of the list and now seems like the right time to also change the way my bilge pumps are powered. The boat was built with 12 VDC supplied to all three pumps via a breaker. Other than perhaps time on the hard (like when I took this picture), that breaker has never been off.

I need a new spot for a new breaker and that seems like the best candidate. My plan is to remove the 15 amp breaker and replace it with a new Blue Sea 30 amp breaker to power a new davit motor.

Question is, what is the best approach for powering the bilge pumps. My plan is to add a small "3 port" bus bar and wire that to the main DC bus, then move the three positive leads (one from each bilge pump) from the connection at the breaker to the new bus. The ground wires should be fine as is. What am I missing?

I need a new spot for a new breaker and that seems like the best candidate. My plan is to remove the 15 amp breaker and replace it with a new Blue Sea 30 amp breaker to power a new davit motor.

Question is, what is the best approach for powering the bilge pumps. My plan is to add a small "3 port" bus bar and wire that to the main DC bus, then move the three positive leads (one from each bilge pump) from the connection at the breaker to the new bus. The ground wires should be fine as is. What am I missing?