Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

Draining hot black oil into a pan under the engine was getting really old, especially as I have to tilt the pan through about 45 degrees to get it out! I like to warm up the oil and then pull the oil pan drain plug - the faster flow rate cleans things out better than sucking it out through the dipstick hole. Replacing the oil pan drain plug with a valve and hose-barb seemed like the answer.

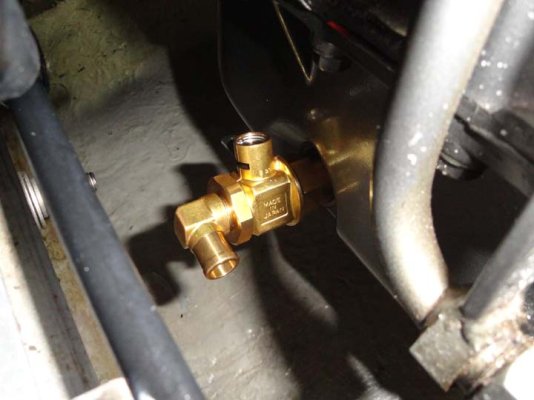

Fumoto of Japan was the only company I could find that makes them - marketed in the USA by Qwik-Valve. They are beautifully machined out of brass and stainless. The on/off lever is spring loaded and has a detent which prevents it being moved accidentally. The valves are around $40 each. For drain plugs that are slightly recessed into the side of the oil pan (mine is), Fumoto makes a screwed spacer/adapter to get around this - about $8 if required. They seem to make valves to fit most engines. Pic shows valve and spacer in place on the oil pan.

A small impeller pump and some hose completes the setup. It would be possible to pump fresh oil into the engines too. I don't because I have good access to the top of the engines and can pour the oil in directly. This morning I added slightly too much. The new valve made it is a snap to drain out the extra into a small pot. Changing oil is now as much fun as it is ever likely to be without a dedicated hard-piped oil change system.

A word of caution: The valve screws into the oil pan with a fiber washer making the seal. For some strange reason, the adapter is supplied with an O-ring instead of a washer. This doesn't work unless your oil pan is machined to accept an O-ring. Order a spare washers with each adapter.

Fumoto Valve | Qwik Valve™

No affiliation, just a satisfied customer etc etc.

Fumoto of Japan was the only company I could find that makes them - marketed in the USA by Qwik-Valve. They are beautifully machined out of brass and stainless. The on/off lever is spring loaded and has a detent which prevents it being moved accidentally. The valves are around $40 each. For drain plugs that are slightly recessed into the side of the oil pan (mine is), Fumoto makes a screwed spacer/adapter to get around this - about $8 if required. They seem to make valves to fit most engines. Pic shows valve and spacer in place on the oil pan.

A small impeller pump and some hose completes the setup. It would be possible to pump fresh oil into the engines too. I don't because I have good access to the top of the engines and can pour the oil in directly. This morning I added slightly too much. The new valve made it is a snap to drain out the extra into a small pot. Changing oil is now as much fun as it is ever likely to be without a dedicated hard-piped oil change system.

A word of caution: The valve screws into the oil pan with a fiber washer making the seal. For some strange reason, the adapter is supplied with an O-ring instead of a washer. This doesn't work unless your oil pan is machined to accept an O-ring. Order a spare washers with each adapter.

Fumoto Valve | Qwik Valve™

No affiliation, just a satisfied customer etc etc.