Snapdragon III

Senior Member

- Joined

- Sep 1, 2016

- Messages

- 415

- Location

- USA

- Vessel Name

- Snapdragon

- Vessel Make

- Custom 56' Skookum trawler

As I have posted elsewhere on this forum I bought a new, used boat last winter, and just finally got it home to Anacortes WA from Hawaii this July. One of the big projects I knew I would need to tackle upon getting it home was installing heat in the boat. It had apparently originally had a heating system, but it had been completely removed. It is a 56' boat with 3 bedrooms, 2 baths, den, dining room, kitchen, and pilot house. Given its size I looked at the options available and decided a hydronic system would be the best.

The three options I could find for hydronic systems, were Webasto, and Olympia boiler from Sure Marine, in Ballard, and Kabola from Marinetec in Anacortes. I met with both companies and they were both very helpful and seemed like first class operations, and in the end decided to go with the Kabola. I liked the idea of having a true water jacketed boiler system that was designed for continuous operation, and of the Olympia, or Kabola, the Kabola seemed like it was more specifically designed for the marine environment, and not adapted from home heating use. The biggest downside to the Kabola is that the controls and pump run on 220 50hz power, so it will need its own dedicated inverter, that I assume will use a little more power than just running it off the 120v inverter I already have running for my refrigeration and other house loads.

The system will have Kabola compact 7 boiler, 23884btu's, with 10 fan coil units, and 6 control zones. It will also have at least 1 heat exchanger of the heating loop of one of my main engines to grab heat when running, and it will also heat the hot water tanks. I am still working out the details of the hot water heating, and if I want to go with heat exchangers on one engine only, or on both engines.

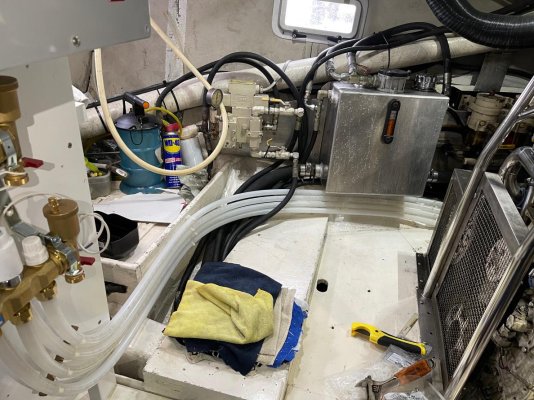

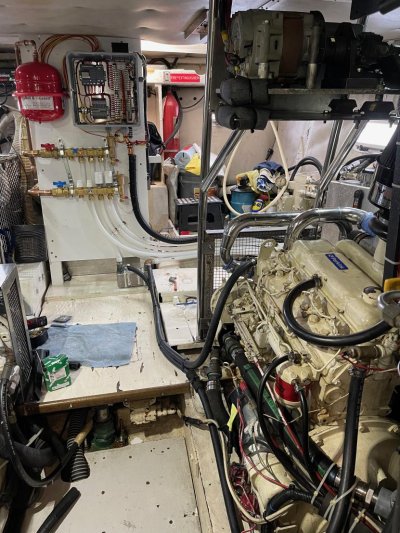

The only real place to put the boiler is in the engine room of the boat, but space is tight in there. Prior to my purchase hydraulic stabilization/stern thruster/alternator were added, and they took up a lot of the extra elbow room the engine room has. Also, there is a overhead hatch in the back corner that has to stay clear below it as it is the emergency escape path for the master bedroom.

The three options I could find for hydronic systems, were Webasto, and Olympia boiler from Sure Marine, in Ballard, and Kabola from Marinetec in Anacortes. I met with both companies and they were both very helpful and seemed like first class operations, and in the end decided to go with the Kabola. I liked the idea of having a true water jacketed boiler system that was designed for continuous operation, and of the Olympia, or Kabola, the Kabola seemed like it was more specifically designed for the marine environment, and not adapted from home heating use. The biggest downside to the Kabola is that the controls and pump run on 220 50hz power, so it will need its own dedicated inverter, that I assume will use a little more power than just running it off the 120v inverter I already have running for my refrigeration and other house loads.

The system will have Kabola compact 7 boiler, 23884btu's, with 10 fan coil units, and 6 control zones. It will also have at least 1 heat exchanger of the heating loop of one of my main engines to grab heat when running, and it will also heat the hot water tanks. I am still working out the details of the hot water heating, and if I want to go with heat exchangers on one engine only, or on both engines.

The only real place to put the boiler is in the engine room of the boat, but space is tight in there. Prior to my purchase hydraulic stabilization/stern thruster/alternator were added, and they took up a lot of the extra elbow room the engine room has. Also, there is a overhead hatch in the back corner that has to stay clear below it as it is the emergency escape path for the master bedroom.