Butch Hammel

Member

- Joined

- Dec 11, 2019

- Messages

- 8

- Location

- United States

- Vessel Name

- Bella Vita

- Vessel Make

- Mainship 400

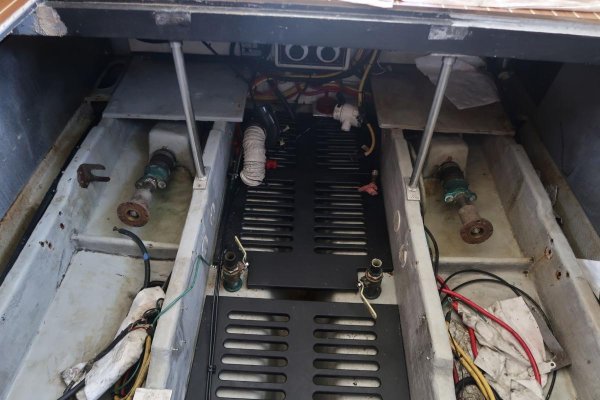

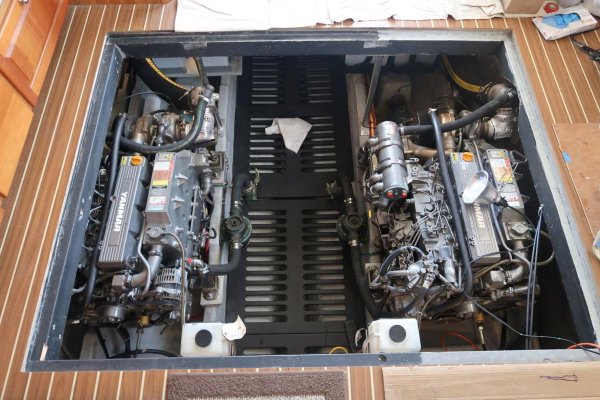

I recently discovered that my starboard tank has a slow leak. I have not read much in this forum of folks having problems with the aluminum tanks in the 400. Has anyone had a leaking tank? What was the cause? Looks like this is very difficult to remove and replace. Has anyone had to replace a tank and how did you resolve it? I can see possibility to cut tank up and remove in pieces and put in smaller tanks all connected or cut out the hull and replace the whole tank. I am in touch with my insurance company and they are sending a surveyor to assess. Appreciate hearing from any who have faced this problem - and specifically for the 400 aluminum tanks - what was the cause - and how you resolved it.