All,

I'm considering building a side overhand for shade on a Mainship 430.... similar to what's on the MS 400.

Looking for a really strong, light weight material other than marine plywood. Nidacore, HDPE, Acetal, others??

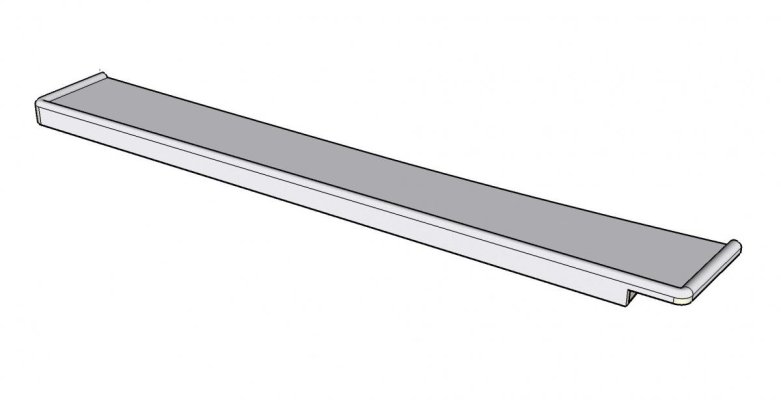

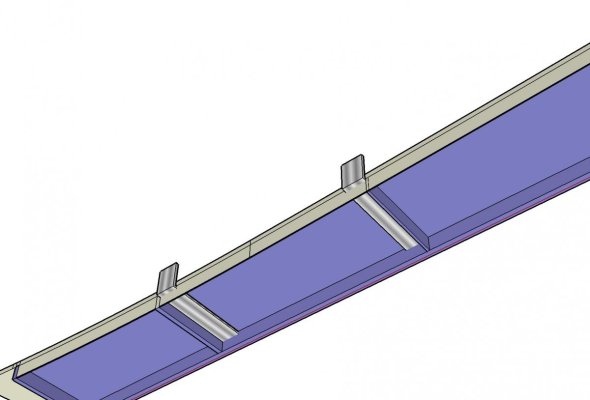

Right now planning on it being 12 ft long, 20" wide and 4" thick, supported by bolts and a backing plate from the side panel behind the seating on the flybridge.

Pix are approximate... I'm not an artist. The first pix is from the 400.

I'm considering building a side overhand for shade on a Mainship 430.... similar to what's on the MS 400.

Looking for a really strong, light weight material other than marine plywood. Nidacore, HDPE, Acetal, others??

Right now planning on it being 12 ft long, 20" wide and 4" thick, supported by bolts and a backing plate from the side panel behind the seating on the flybridge.

Pix are approximate... I'm not an artist. The first pix is from the 400.

Attachments

Last edited: