Gdavid

Guru

Groco makes an external strainer/scoop that mounts a bronze ring on the bottom of the hull, and the strainer/scoop is mounted with screws so it is removeable. Doesn't allow clearing with a stick, but you can dive on it to remove the screen and clean it out.

https://www.groco.net/products/raw-water-strainers/hull-strainer/sc-series

If you do decide to add a scoop/strainer at some point, you might look into that series as a compromise on serviceability.

This does look like a great option, thanks for pointing it out. Might be something I add on the next haul out. In my area we rarely get large amounts of grass floating on the surface or suspended. I don't have any plans to venture very far with the boat this season but hopefully next season I will have finished going through the major systems and venturing further. When the boat comes back out of the water in the fall, I plan to have it soda blasted and left to dry out over the winter so I would probably just 5200 the ring to the barrier coat.

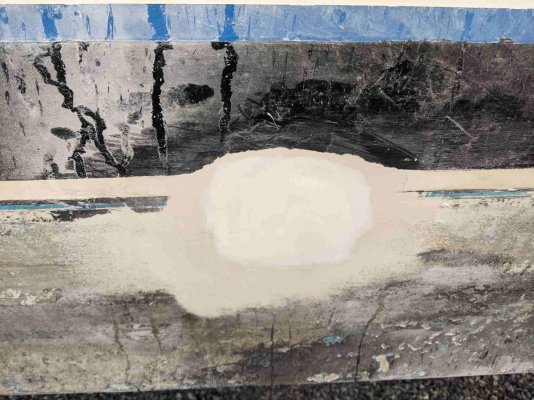

On Saturday, I was fortunate to have my father lend a hand in the yard for a pretty full day, he tackled the loose paint around the water line while I worked on my hull projects, I'm much closer to being ready to roll paint back on.

Last night I hit a couple minor snags assembling my engine intake plumbing. I ordered the wrong pipe thread to hose nipple adapter, 1.5" to 1.75" instead of the 1.5" to 1.5" that I need, I also realized that the hose between the thru hull and the strainer was 1.25" rather than 1.5", which is the size between the strainer and engine and then I believe the hose size running between the cooling components. So I'm remedying this situation of course with new hose and fittings on the strainer to stay 1.5" the whole way.

A short job or replacing my bilge pump hose turned into another unexpected ordeal. I removed and trashed the old one while cleaning the bilge, which is the only effective way I know to clean any sort of oily corrugated hose. The thru hull for the outlet is outboard of a large wooden battery box which houses 2 of my 4 group 31 batteries and the only way to reach it is disconnecting the batteries, unscrewing the 8 wood screws half with partially stripped heads. Apparently the last person to tackle this task took a shortcut and just spliced the bilge hose just inboard of the battery box rather than moving it, could have been the same genius who installed a 1.25" hose to feed a 1.5" cooling circuit. At any rate, that monkey business is now remedied with a new, continuous length of hose.

I also bit the bullet and ordered a new AC for the boat, the dometic unit on the boat, which is only about 5 years old, took a lot of abuse running with a loose connection in the shore power system as well as the 1.5 kw promariner inverter attempting to power the unit whenever left unattended and the shore power went out. I rewired the inverter to remedy this problem but it appears that permanent damage to the AC occurred. It will run for a while then start acting haywire, I'm not sure if the compressor is going out or something in the controls is damaged but at this point I'm replacing it with a Cruise Aire (with an "e") and will see about having the Dometic Unit repaired as a spare or to sell. My wife likes to use the boat as an office and I really need to prioritize her uses as I'm dumping a copious quantities of time and money at the boat.

Last edited: