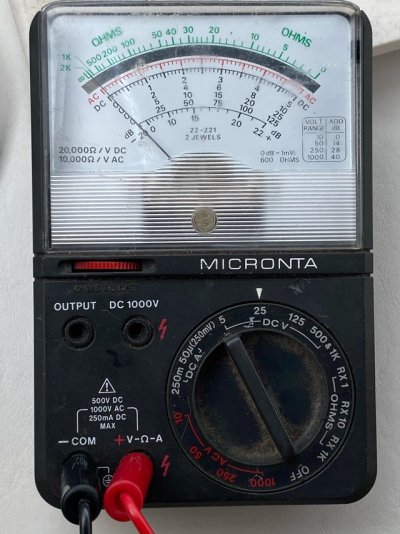

Try turning off your battery chargers, solar, etc, putting a volt meter directly on the windless connections, and operating the windlass for 3-5 seconds under no or light load.

-- See what the voltage measures before, during, and immediately after the brief load test.

-- Check the voltage at the battery immediately before and after the load test.

-- See if there is a significant voltage drop between the battery and the windlass.

-- And, also see if the voltage falls off really quickly with minimal use.

One goal is to demonstrate that it isn't a battery problem by making sure that the chargers don't mask it before you can find it (I know you said they are new, but one could be bad, happened to me).

Another goal is to demonstrate that it isn't a wiring or connection problem by being sure there is no voltage drop.

If it is demonstrated that it is neither, I'd take the motor out and to a local electrical shop. They will often test them for nothing or a very nominal fee. Some repairs may be more expensive than others, e.g. rewinding the motor vs resoldering a bad connection. But, once they tell you what is up, you can decide to get it fixed, replace it, or look for a new windlass.

I have never used one of those windlasses. I was going to get one without thinking too much about it because the makers of my bow pulpit deal in them. But, the reviews I read really weren't good, so I decided to go to the other end of the spectrum with a Lofrans Tigres.

A friend had some problems with his windlass. He brought it to a local shop and they charged him $100 to fix some internal connections that were apparently problematic. So, there is hope of an inexpensive fix in that space, I just don't know how common it is.

I don't me to be down talking your windlass. As I mentioned, I've never had one. Instead, I just intend to suggest a way to isolate the problem to the battery, wiring or windlass, and go from there.

I think it unlikely that it is gearing, unless you hear it slipping. But, you could always take it apart and look for any signs.

Happy hunting!