Ron, that is pretty impressive.

I really like the idea of the washer, but I don’t want to have that large of a hole in the surface fiberglass. Instead, I want to drill a 1/2” hole in the deck, and then use a Dremel to undercut the plywood.

However, I think that washer idea is elegant. I’m working an idea in my head that would accomplish the same thing without burying the washer in the epoxy.

Incorporating many of your suggestions, here is what I’m thinking at the moment. I’m still waiting on confirmation but I believe the total thickness of the deck where I’m working is 1.75” thick. If this is the case, here is what I’m considering.

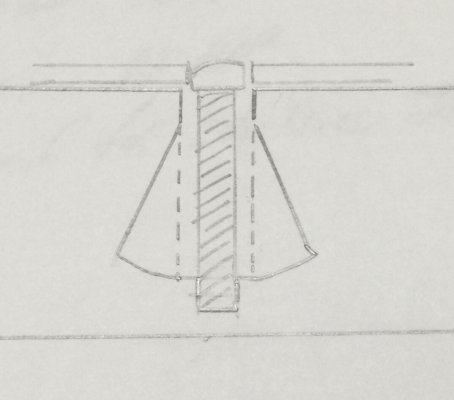

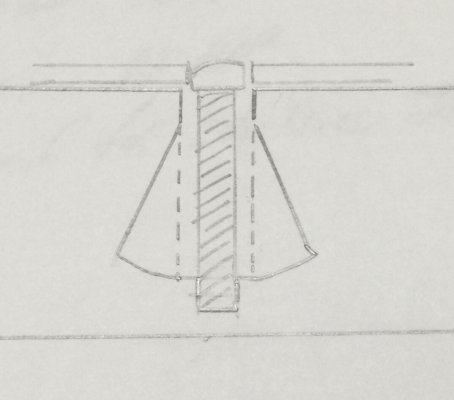

Start off doing what I did before, drill a 1/4” hole 1.5” deep. Follow that with a 1/2” hole 1.25” deep. Then using a Dremel, undercut the plywood under the surface fiberglass. This will result in an almost cone like area under the fiberglass with a 1/4” deep extension underneath it.

I’ll then make up a template, again from the deck mounts themselves, but instead of a 1/4” hole in the template, I’ll use a 15/32” hole which should be just large enough for the head of the machine screw.

As before, I’ll fill the cavity I have created with thickened epoxy about 3/4 full, then insert a 1.75’ machine screw that I’ve waxed and then coated with epoxy into the cavity getting it all the way down into the bottom 1/4” well at the bottom. Fill the rest of the cavity with epoxy and level the top.of the epoxy. Again, much as you have done in your example. However, then I’ll put the template with the 15/32” holes over the screw heads and align the template into position. This will center the top of the threads with the holes for the deck plates.

I’ll use inexpensive machine screws for this and then use good quality 1.25” 316 Stainless machine screws for the final assembly.

Some details I need to figure out such as what material to use for the templates. How to ensure I don’t bond the template to the deck. Make sure that the registration for the templates is accurate etc…. If I can figure those things out I’ll do a test on scrap to see if it works out. Here is a simple diagram of the basic idea.