epowermarine

Member

- Joined

- Mar 29, 2021

- Messages

- 11

There is a long story behind this, but I'm going to stick with the short story for now. My VW Marine engine is full of salt water, and I'm replacing it with a new D3 220hp. This will happen at my marina in Florida, and I'm guessing that this project has never before taken place in the US. I'd love to hear from anyone who has done this conversion in Europe or anywhere for that matter as I could use the help.

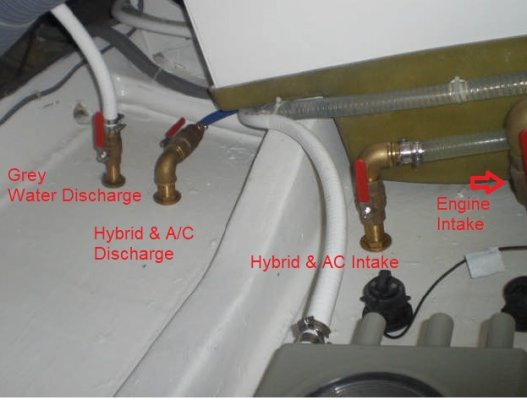

Instead of a sad story we are looking at this as a huge upgrade to our beloved Solmate, a 2011 model. We have decided to loose the Iskra hybrid functionality as it would add another $$$ to the amount that this little job will already cost, and the truth is we never use the emotor down here with all the stiff currents and boat traffic anyway. We will miss the 48v generator but I can do something with a 48v alternator or perhaps a DC/DC converter (figure that one out later).

The new Volvo has been on order for 2 months already, and I'm told it's going to be another month, who knows. Soon I will start the deconstruction of the VW with only 400 hours on her. I will definitely have some spare parts available if anyone is interested as many parts of the engine and hybrid system are in perfect shape.

Once done, the boat will have the little bit of extra power that we need for realistic trips down to the keys, to the Bahamas, and such. Really looking forward to being finished but there is so much work ahead of us to get there.

All for now, I plan to document as much as I can for future conversions. At some point everyone will have to repower so it could be a useful resource.

Todd

Instead of a sad story we are looking at this as a huge upgrade to our beloved Solmate, a 2011 model. We have decided to loose the Iskra hybrid functionality as it would add another $$$ to the amount that this little job will already cost, and the truth is we never use the emotor down here with all the stiff currents and boat traffic anyway. We will miss the 48v generator but I can do something with a 48v alternator or perhaps a DC/DC converter (figure that one out later).

The new Volvo has been on order for 2 months already, and I'm told it's going to be another month, who knows. Soon I will start the deconstruction of the VW with only 400 hours on her. I will definitely have some spare parts available if anyone is interested as many parts of the engine and hybrid system are in perfect shape.

Once done, the boat will have the little bit of extra power that we need for realistic trips down to the keys, to the Bahamas, and such. Really looking forward to being finished but there is so much work ahead of us to get there.

All for now, I plan to document as much as I can for future conversions. At some point everyone will have to repower so it could be a useful resource.

Todd