Bkay

Guru

- Joined

- Aug 8, 2018

- Messages

- 580

- Location

- United States

- Vessel Name

- Wingspan

- Vessel Make

- Aluminum Catamaran

Good morning. I have communicated with a few of you over PM while building my specifications – thank you to those who provided good food for thought! At the suggestion of one of our members, I’ve decided to try documenting the build of a new boat.

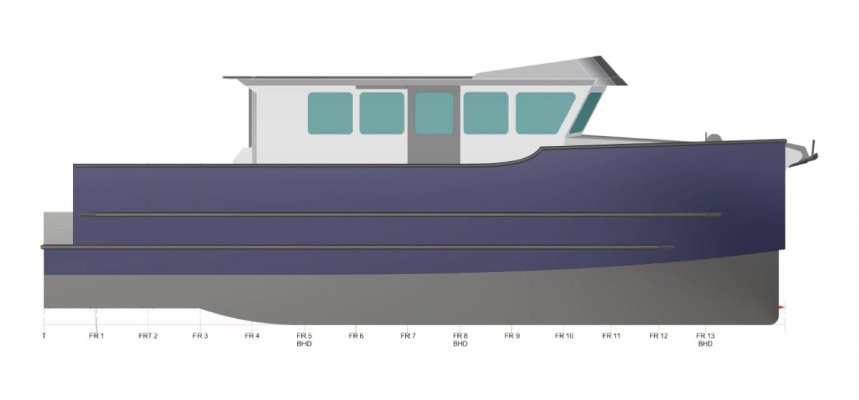

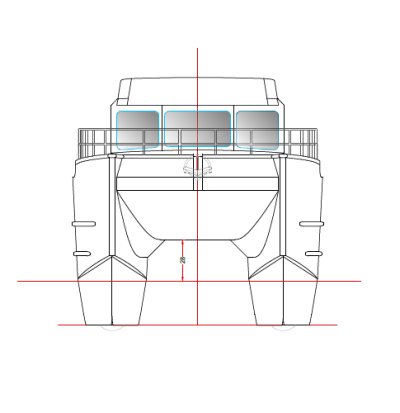

The vessel is a 38’ x 14’ x ~2’ semi-displacement, aluminum catamaran being designed in Canada. This is my second new boat build and my first aluminum boat. After many years of having both wood and fiberglass boats – mostly “yacht finish” boats – I’ve decided to experience the pleasure and pain of aluminum for a change of pace. However, I’m getting too old to continue painting and varnishing (and was frankly never very good at either) so I’m keeping the exterior of this straight up workboat finish and leaving her unpainted above the waterline. Interior will be a little more “yachty”, but not too much.

She will be powered by two M-1 rated John Deere 4045’s. They will produce 160 hp at WOT of 2300 RPM and should hit my target speed of 14 knots without too much effort. She is in design stage, but we anticipate a fully loaded displacement in the 25,000 lb range (hopefully a little lighter). I’ll do my best to post the type of info that I find interesting when looking at other people’s build threads. I’ve learned from a number of people over the years and figured I’d pay the favor forward if anyone else is considering an aluminum or cat build.

Oh, as an aside, I don’t usually post on forums and I have a pretty bad sense of humor – so I’ll apologize in advance if inadvertently offend anyone. My wife usually proofs my emails to make sure I’m behaving in public but she’s not participating in this thread. ��

Now - to see if I can upload a couple perspectives.

The vessel is a 38’ x 14’ x ~2’ semi-displacement, aluminum catamaran being designed in Canada. This is my second new boat build and my first aluminum boat. After many years of having both wood and fiberglass boats – mostly “yacht finish” boats – I’ve decided to experience the pleasure and pain of aluminum for a change of pace. However, I’m getting too old to continue painting and varnishing (and was frankly never very good at either) so I’m keeping the exterior of this straight up workboat finish and leaving her unpainted above the waterline. Interior will be a little more “yachty”, but not too much.

She will be powered by two M-1 rated John Deere 4045’s. They will produce 160 hp at WOT of 2300 RPM and should hit my target speed of 14 knots without too much effort. She is in design stage, but we anticipate a fully loaded displacement in the 25,000 lb range (hopefully a little lighter). I’ll do my best to post the type of info that I find interesting when looking at other people’s build threads. I’ve learned from a number of people over the years and figured I’d pay the favor forward if anyone else is considering an aluminum or cat build.

Oh, as an aside, I don’t usually post on forums and I have a pretty bad sense of humor – so I’ll apologize in advance if inadvertently offend anyone. My wife usually proofs my emails to make sure I’m behaving in public but she’s not participating in this thread. ��

Now - to see if I can upload a couple perspectives.

Last edited by a moderator: