Anyone having trouble with engine shake?

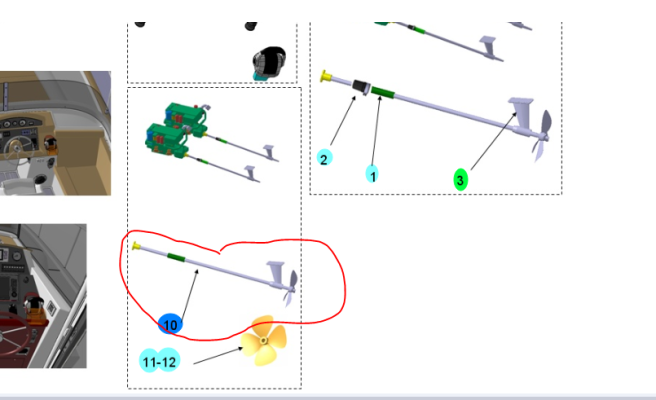

There is only 1 bearing in the P bracket and then shaft is bolted onto the gearbox.

I have had a bit of engine shake at 2000 revs. It is better now that I have the engine alignment done but it was not an easy job.

Lets start with make/model/year Swift Trawler/if twin engine, what side vibrating

I have a ST44. It had a vibration around 1900-2100 RPM since new. I avoided that RPM. Prop checked twice. This winter I decided to dive into it

Yard was sure it was the rear engine mounts so they changed, re-aligned, now vibration worse and a wider range of 1000-2700 RPM. Not good

They removed the shaft, machine shop said its bent (they put on lathe with dial gauge). How that happened who knows couldve been on transport ship from Europe to USA, yard/dealer crane error when boat was being loaded / unloaded, something the first dealer did (i.e. run aground, suck up dock line). The vibration was there day one when the boat was first sold, noted during the initial sea trial, and by Volvo tech that looked over engines to activate warranty. Thankfully I had it clearly documented to support the warranty claim with Beneteau.

Another ST44 owner had a similar vibration on the same side and it turned out to be his shaft-to-coupling fit-to-face and once he had that corrected he was good to go (after chasing it for a long time) but my situation doesnt seem to be that easy.

Lots to check: props, cutlass bearing, strut, coupling, coupling fit-to-face, output flange on transmission, shaft, engine mounts, how prop it sitting on shaft/keyed, etc

Someone with a dial gauge and feeler gauge can check most things. If everything is checked with boat in-water / on the hard, the final step is to remove the shaft and check it as well as the strut/cutlass.

I am hopeful this will finally be resolved soon